Horsemeat in processed foods might have been detected sooner if nuclear magnetic resonance (NMR) spectrometers had been used. That, at least, is the claim of Oxford Instruments after releasing its new bench-top NMR spectrometer, Pulsar, in 2013. ‘The fatty acid profiles of meat from different animals are readily distinguishable using NMR, but until recently the equipment to carry out these tests has been too expensive and technically complicated to allow deployment in industrial settings,’ says Ian Robertson, product manager at Oxford Instruments.

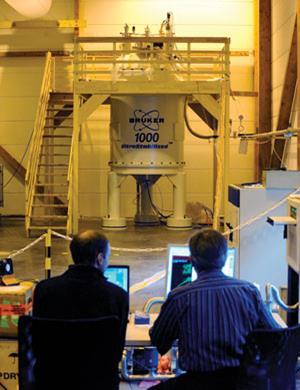

NMR is already used by big industry, and scientists in pharmaceutical companies, for example, have appreciated the benefits of NMR spectroscopy for years. Most notably, it reveals the structure of molecules in a sample, providing more information than some other analytical techniques: ‘NMR flags up something wrong even if you have never seen the flaw before, because you see the whole sample,’ says Andy Gibbs, sales manager for magnetic resonance at Bruker UK, comparing it to techniques that test samples for a pre-determined substance. The principle parts of an NMR spectrometer are a magnet and a probe which goes into the centre of the magnetic field and contains the sample. When placed in the magnetic field, spin-active nuclei will interact with the field and adopt certain orientations, or spin-states, with respect to the field.

Applying an alternating magnetic field (usually radiofrequency radiation) mixes up the nuclei between the states and as they rearrange themselves back again, they emit signals that reveal the structure of the sample. But the energy differences between the spin states are very small, so the population differences between the spin states are also very small. This means NMR, although information-rich, is a relatively insensitive technique as only a small proportion of the nuclei in a sample generate the signal. As well as providing more comprehensive information than some other techniques, it is also non-destructive.

Small successes

Bench-top appliances promise to popularise and perhaps extend the industrial reach of NMR, and they are the latest product innovation. As far as industry is concerned, it could become more widely used in quality control in food and other sectors. Main rivals currently jostling for leadership in bench-top NMR include Oxford Instruments and Thermo Fisher, which has produced two bench-top instruments in the last couple of years. About the size of a large computer printer, all are portable and perhaps half the price (around £50,000) of larger machines used in research laboratories or big industry. However, none is as sensitive.

Yet sensitivity improvement in NMR is the long-term concern of experts. ‘We are always pushing the sensitivity boundaries a few points further,’ says Craig Butts of Bristol University in the UK. The sensitivity of the analysis depends on a wide range of factors, such as the strength of the magnet, wiring technology, type of solvents used, type of probe and amount of background noise and vibrations from electronics. Technologies resolving some of the problems have created new demand from scientists, leading to fresh problems. This has in turn generated a new cycle of innovation.

With a 45–80MHz permanent magnet, bench-top NMR is a relatively weak tool when set alongside increasingly powerful superconducting magnets now reaching maximum levels of 1GHz in larger spectrometers and expected to reach 1.2GHz in a couple of years. These are available for mainstream scientific and industrial applications.

‘Bench-top is never going to compete with full spectrometers, because it is neither sensitive enough nor does it provide a high enough resolution. However, it is in a different market niche,’ says Gareth Morris of Manchester University in the UK. Thermo Fisher’s leading 45MHz picoSpin spectrometer, available since 2011, is thus mainly targeted at educational institutions for testing known molecules. Its picoSpin 80, which resonates at 82MHz, was launched in September 2013 and is aimed more at research applications. Both Thermo Fisher and Oxford Instruments’ bench-top spectrometers contain permanent magnets.

We are always pushing the sensitivity boundaries a few points further

‘Two things have affected the development of bench-top – more powerful smaller magnets and the fall in the price of complex electronics,’ says Morris. For Thermo Fisher and Oxford Instruments, the magnet improvements (using rare earth metals, for example), combined with portability, mean the spectrometers could be sold into new applications and markets. They could also perhaps compete with the lower field superconducting magnet spectrometers.

‘300MHz is the smallest of the big spectrometers. PicoSpin’s 80MHz is one quarter of that. But it does not provide one quarter of the capacity or chemical information,’ argues Mark Dixon, NMR product marketing manager at Thermo Fisher. Dixon claims that the company may have found a ‘sweet spot’ of research capacity that could meet the analytical needs of a section of the research community. Bench-top instruments could also provide other advantages. When used alongside larger spectrometers, they could filter out less important research, freeing up more time for the more sophisticated tests on the larger machines. Service and maintenance costs are also considerably lower for bench-top NMR.

Cool spinnings

By comparison, the titans of NMR spectroscopy, Bruker, JEOL and Agilent, produce instruments that need large amounts of expensive aftercare in addition to the product cost. Agilent purchased instrument rival Varian in 2009 and buyers indicate it has since been reviewing its market and product range. Bruker is known for innovation in cooling technology, while JEOL is famous for its probes. Probes used usually differ according to the size of the sample and the type of nuclei observed, as well as a range of other factors. Bruker was the first company to market cryoprobes, which made a significant impact on research. Another producer, Magritek, makes a number of products, including low field magnet spectrometers.

‘Helium-cooled probes transformed the technology and led to at least a five-fold increase in sensitivity. It has been the greatest advance of the last 10 years,’ comments an NMR scientist at a leading agribusiness who did not wish to be named. This is because cooling to liquid helium temperature makes the background noise lower. However, he notes eye-watering costs. ‘The electricity bill each year for one cold probe system, keeping it at –220°C, adds up to £6000. On top of that is the cost of the probe and cryosystem itself, which can amount to at least £100,000,’ he adds. However, room temperature probes are also available.

Buyers take slightly different views of the three major manufacturers. ‘I would seriously consider all three,’ says the agribusiness NMR expert. ‘They are bespoke pieces of equipment and the price depends on how desperate they think you are to buy from them and how much they think they can get. There is not much to choose between them but Bruker is more engineering-focused while Agilent has a magnet factory in the UK so provides more support for its magnet systems,’ he says. Producers develop expertise not just in making the spectrometers but in helping and educating the customers, as the instruments are complex.

Bristol University’s Craig Butts adds ‘I couldn’t see much difference in hardware but in software and how easy the spectrometer is to use. All the producers have bespoke software. Agilent has solid production values in terms of hardware and probes, which are very robust and systemised, while Bruker is very bespoke and builds to order.’

The producers themselves, however, are clear about their differences. ‘We offer pretty much everything for the most complete range of requirements, and we have bigger magnets that do all manner of things in all shapes and sizes. If you buy one of our spectrometers and need a specific probe, we’ll supply it,’ says Bruker’s Gibbs, a comment backed up by Morris: ‘Bruker’s success is partly based on its flexibility in terms of finance and supply,’ he says. Meanwhile, JEOL’s claim that it has the best and fastest probes in the world is also echoed by buyers.

Bruker’s development of cryoprobes more than a decade ago broke new boundaries in research. But it has created new problems, because helium is becoming scarcer. To resolve this, Bruker invented a new type of cooling system using nitrogen. ‘The Bruker probe cooled to liquid nitrogen makes the technology simpler and cheaper. There has been a big growth in nitrogen-cooled probes in the last few years,’ notes Morris. JEOL followed suit. However, there is a trade-off: nitrogen-cooled probes are not as sensitive as those cooled by helium.

Meanwhile, Japanese producer JEOL’s spinning probes also had a progressive effect. ‘JEOL has taken the speed of probes to a whole new level,’ claims Steve Brookes, sales coordination manager at JEOL. The figures are impressive. Its 0.75mm solid state NMR probe spins the sample at 110kHz, the world’s fastest spinning speed for NMR, and was launched in 2012.

Probe spinning improves sensitivity and produces higher resolutions, so the new probe is expected to be effective in applications difficult for conventional NMR, including micro-analysis of drugs, natural products and thin films. ‘Spinning probes have been around since the 1950s but they needed a lot of research time to stabilise them at full speed,’ says Brookes, drawing attention to the company’s technical expertise.

Other unique selling points outlined by Brookes include reliability and over-specification. ‘We test all of our systems extensively long before they get to the customer. Selected customers in Japan test it out first so that teething problems are sorted out. Also, the customer won’t be let down because the specs are set according to minimum performance rather than average, so the product will do better than that,’ he explains.

Two state solution

Major steps have been made in the last 20 years in liquid state NMR, and new ones are expected. ‘In the last ten years, robotics and improvements in sensitivity have led to more simplicity and ease of use,’ says Morris. Robotics have helped automate the sampling procedures, for instance, creating higher throughput and a more user-friendly interface. Among the innovations Morris expects in future are an increase in the use of magnets with low helium consumption, and incremental improvements in magnet design and technology. But Morris does not expect new markets to develop for the very large expensive spectrometers.

Every so often a new idea makes a big impact

Solid-state spectrometry has particularly improved over the last decade, and instruments may be two or three times the price of liquid-state counterparts. Major producers make both solid- and liquid-state spectrometers. The former often require higher field magnets and can be used, for instance, to study the structure, function and dynamics in large biological molecules, such as proteins and large DNA molecules. The development of faster spinning probes has been particularly useful for solid-state NMR. ‘With NMR you need a nice sharp [data] peak, but this spreads out with solid. Interactions are time-dependent so by spinning faster you are averaging them out,’ says Brookes. This narrows the peak.

According to Gibbs, change in solid state NMR is due to improved hardware and ease of use, automation and better spinning. ‘This robust reliable operation opens the technique up to “normal” scientists in industry as well as researchers in universities. Along with this increase in “easy” solids, this hardware has helped enable a lot of research in new techniques, meaning there is now also a tremendous range of extra information that can be obtained from solid samples,’ he explains.

Further unusual techniques are available, such as ‘magic shimming’, which produces clearer solid-state data that looks like that obtained from liquids. Morris points to the development, as yet uncommercialised, of hyper-polarisation: increasing the population difference by transferring polarisation from a much more polarised nucelus. ‘You get very, very strong signals from the polariser, which could improve sensitivity by hundreds or thousands of orders of magnitude,’ says Morris.

Meanwhile, Robertson of Oxford Instruments already foresees new developments in bench-top NMR spectrometers. He predicts they will come as a standardised application. ‘They will be programmed to do a specific task. We are collaborating with various food industries to develop this method,’ he says. As Morris points out, NMR is a mature principle, but plenty more fun can be expected in future. ‘Every so often a new idea makes a big impact,’ he says.

Elisabeth Jeffries is a science writer based in London, UK

No comments yet