Rather than a potential triumph, the compostable plastics we use look increasingly like a tragedy. Andy Extance looks at the problems and seeks solutions

When the BBC’s Blue Planet II aired in 2017, showing turtles trapped in plastic debris and puffins feeding plastic to their chicks, the material became public enemy number one. Half of British people said they’d pay more to avoid plastic waste according to a poll by survey company YouGov. Compostable plastics are among the solutions, yet they typically can’t go on your compost heap at home. Worse still, few UK facilities can compost them, reveals Philippa Roberts, co-founder and chief executive officer of Binit Group, in Exeter, UK.

Rather than composting, in the UK food waste typically goes to anaerobic digestion, in which bacteria mostly chew it up to make fertiliser and methane gas. But digesters can’t break down most compostable packaging. Yet, Roberts tells Chemistry World, packaging still gets included with food, only to be separated out at anaerobic digesters and then sent to incinerators. Only the more populous regions, principally London, can successfully compost the packaging, she asserts. ‘This is nuts,’ says Roberts. ‘Why are we putting all this in the composting and then pulling it back out again and burning it?’

Current UK law means that much single-use packaging, such as salad containers, can no longer be more conventional recyclable plastics. But Roberts says that compostable packaging ‘probably has a worse environmental outcome’. ‘I hate plastic, but a plastic salad pot is readily and easily recyclable, and a compostable one isn’t,’ Roberts says. ‘The compostable product tends to be more expensive as well.’ Binit is therefore trying to include more compostable packaging in anaerobic digestion – but so far hasn’t been able to get the data to help do so.

Roberts mainly wants data about how compostable packaging behaves in anaerobic digestion. Yet the messy overall situation poses broader questions. While the challenges are strongly influenced by plastics’ chemical properties, they extend across society more widely. Many of this article’s interviewees think that clearing up the problem will primarily involve new, more carefully considered laws. Some are developing new technologies that could offer solutions. But others, like Roberts, think we already have some answers at hand.

Solving numerous problems?

Mario Pagliaro from the Institute for the Study of Nanostructured Materials (ISM) of Italy’s Research Council in Palermo is a strong proponent of compostable plastics. In 2019, Pagliaro and his ISM colleague Rosaria Ciriminna published a review predicting a sharp increase in growth of biodegradable and compostable plastics. Pagliaro tells Chemistry World that companies should develop ‘packaging using truly biodegradable polymers available in large amounts at affordable cost’. ‘The problems posed by non-biodegradable plastics are too numerous and are impacting the environment and public health on a real global scale,’ he stresses. According to European Bioplastics, approximately 1.5 million tons of biodegradable and compostable plastics were produced in 2021, representing 0.4% of the total plastic market.

One company already processing that compostable packaging is Recorra, based in London, UK. It processes items that can include polylactic acid (PLA), produced by fellow British companies Vegware and Scrummi. According to Tom Mockridge, Recorra’s strategy director, materials used must be certified to European industrial composting standard EN 13432. Industrial composting usually requires two steps, a first ‘active composting’ stage that happens in a dedicated vessel at temperatures up to 70°C, and a second maturation step. The whole process must be complete within six months.

Recorra’s customers pay it to collect dedicated bins from sites that use such EN 13432-certified packaging. It screens bins to make sure they have little contamination with non-compostable material before shipping packaging to specialist Envar. Based in Huntingdon, UK, Envar uses an in-vessel composter, which raises the waste’s temperature above 60°C for 48 hours. This sterilises it and enables hydrolysis reactions that efficiently break down PLA, Mockridge explains. Envar then leaves the compost outdoors for around 10 weeks, screens it for anything that hasn’t been broken down, and sells the compost.

Costs for Recorra include ‘gate fees’ it pays Envar to take waste, though these are lower than what incinerators or landfill waste sites charge. ‘The quality screening process and the fact that collections are in small volumes adds to the costs,’ Mockridge says, yet ‘this route is fully viable’, he adds.

Binit, however, was unable to set up an in-vessel composter. In southwest England, volumes of compostable plastic collected would have been too low to make it viable, Roberts says. By contrast, anaerobic digestion can earn more because digesters can burn the methane they produce to generate electricity, she adds. They also charge more for accepting waste. The process heats waste to higher temperatures, but for less time than in-vessel composting, Roberts says. Compostable plastics therefore don’t break down as fully in a digester, she comments.

Untried conditions

Anaerobic digestion must also liquify and pulp all materials so that they can pass through narrow tubes, Mockridge explains. Digesters therefore generally remove all packaging and send it for incineration. Some test installations, primarily developed by Aerothermal in Poole, UK, have tested putting cellulose-based paper, card and compostable plastics into pumpable liquid, Mockridge says. This technology has not been widely deployed, he adds.

There’s very little research to back up a lot of the compostable plastics on the market

The heated conditions that EN 13432 requires are very different to what people generally understand by composting, explains Andrew Dove from the University of Birmingham in the UK. We usually think that means putting waste in a bin in our garden and leaving it. Around half of us believe that biodegradable plastics should break down in less than a year, he says. The prEN 17427 (2020) home composting standard is based on a 12-month process at up to 30°C. But Dove notes that PLA left in the environment degrades very slowly, and even when recycled can readily contaminate polyethylene terephthalate (PET) recycling streams, he adds.

Mixtures of different compostable plastics are also problematic says Teresa Domenech Aparisi from University College London, UK. ‘They’re putting together different things that work slightly differently, and they degrade at different times, under different circumstances’, she says. ‘There’s very little research to back up a lot of the compostable plastics that are put on the market. We have a range of different compostable plastics that have been adopted quickly, they’re not a proven answer to conventional plastics.’

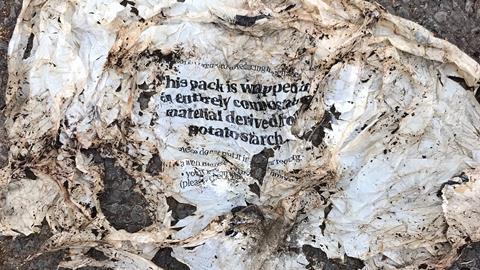

Domenech works with UCL’s Plastic Waste Hub, which ran the Big Compost Experiment, asking what citizens found when they tried to break down plastics at home. The experiment collected their results as pictures and stories. Most items were still intact after a year. Domenech says that some companies making the packaging ‘haven’t really tried the conditions’ they suggest for home composting. She says that companies have introduced compostable packaging in a way that’s ‘rash and careless’. While she knows that the intentions of introducing them were good, she stresses the importance of considering how they fit with existing waste disposal systems.

Chemically controlling composting

Sitting in front of the whiteboard in his office at the University of Wisconsin–Madison in the US, George Huber holds up a large sheet of flexible packaging. It’s a biodegradable plastic film coated in a similarly biodegradable metallic layer. The plastic is polyhydroxyalkanoate (PHA), which is usually rigid, but this flexible version has been developed at great expense by biopolymer company Danimer Scientific. PHA and polyhydroxybutyrate (PHB) are the most biodegradable plastics, but are expensive and hard to produce, Huber explains. PLA is the most widely used compostable plastic by volume, followed by polybutylene adipate terephthalate (PBAT), he adds.

Some companies falsely claim that they can make other plastics biodegradable using additives that break them down into harmful microplastics, worsening environmental impact. For instance, in Mexico, this approach prevents sewer clogs but leads to ocean pollution. In 2013, when she was the attorney general of California, US vice-president Kamala Harris sued two water bottle companies using this approach. Some companies use enzymes to degrade plastics, but high temperatures that manufacturing exposes them to often denature the enzymes, stopping them working. ‘They claim there’s some additive that will magically make the plastic disappear,’ says Huber. ‘That just doesn’t work.’

For plastics to biodegrade effectively, they generally need ester groups in their structure, adds Brian Grady from the University of Oklahoma, US. The proportion and arrangement of ester groups are crucial. Another factor is how rigid packaging is, which is determined by the plastic’s crystallinity, which in turn depends on the plastic chain structure’s regularity, Grady says.

Plastic residues remaining in final compost can be a significant source of pollutants to the environment

Plastics’ crystalline properties give them strength and ductility, explains Dove. But crystalline substances are harder to break down, because other substances can’t easily access their chemical bonds. Crystallinity interrelates with another property, the plastic’s glass transition temperature. Above this temperature the material becomes more rubbery, allowing easier breakdown. Home composting temperatures are typically below PLA’s glass transition temperature, says Dove.

Hugo Barroux, product development manager at natural polymer company Xampla in Cambridge, UK, adds that it takes longer to break high molecular weight polymers like PLA and PHA into smaller molecules. The type and density of chemical bonds in a plastic can also make it harder for microorganisms to gain access and break them down. Barroux adds that mixing different polymers and additives together can be important in how packaging products degrade.

Unfortunately, some additives that compostable plastics include are known to be hazardous, says Cinta Porte Visa from the Institute of Environmental Assessment and Water Research, in Barcelona, Spain. ‘The industry is not required to report which additives are used in the fabrication of different plastic items,’ she adds.

Her team extracted chemicals from four single-use PBAT compostable plastic bags, and four conventional plastic bags and bottles, and investigated the extracts’ toxicity. They particularly focused on what happened if the compostable plastics hadn’t fully degraded. Other than conventional PET water bottles, all the items showed some degree of toxicity. ‘Plastic residues remaining in final compost can be a significant source of pollutants to the environment,’ Porte tells Chemistry World.

How can we tidy up this mess?

For Porte, avoiding toxicity from compostable packaging additives involves ‘political regulations needed to control economic interests/pressures’. ‘We should be able to select and use the safest [additives] for the environment and for human health,’ she says. ‘Industry should be obliged to report which additives are used in the fabrication of each specific item.’

Barroux agrees that policymakers should continue ‘to review regulations on the most polluting plastics’. However, he adds that ‘the industry needs solutions to create new materials that don’t impact the environment’. Xampla produces materials exempt from legal restrictions on single-use plastics. In September 2023, it launched ‘plastic-free, compostable solutions’ under the brand name Morro, based on plant proteins. Packagers can apply Morro to products made of paper, enabling the coated paper to be either composted or conventionally recycled. ‘Without scientific and technical innovations, regulations will have minor impact as there needs to be fit-for-purpose and cost-effective solutions available to use,’ Barroux says.

Dove estimates that the solution to the compostable packaging issue is 70% political and economical and 30% technical. His team has collated evidence to guide policymakers to make decisions. ‘If you decide that anaerobic digestion is the way forward for packaging plastics, do we have the right materials that have the right mechanical and end-of-life performance to do that?’ he asks. Dove cites research from Domenech’s colleagues at UCL as one possible example of evidence that policy should be made on. They found that we would generally prefer to have plastic products labelled with how to dispose of them, rather than what they are.

The market is defined by policies and regulation

To provide technical solutions, Dove’s team is developing compostable sugar-based thermoplastics for medical testing applications, such as Covid testing kits. The project includes collaboration with social scientists to understand how people dispose of these tests and explore any associated risks, particularly regarding used Covid swabs. The Birmingham team is optimising the materials and will collaborate with environmental scientists to test their biodegradability next.

UCL’s Domenech argues that the best solution is to avoid using packaging at all. She adds that it’s technically possible to separate out the different types of compostable plastic and process them. However, it’s not necessarily economically feasible to do so, and Domenech warns that waste management companies do go bankrupt because their processes aren’t profitable. Social and political changes could help, Domenech suggests. ‘The market is defined by policies and regulation,’ she says.

Domenech points to how the UK introduced a tax on plastic packaging that contains less than 30% recycled content. Such measures provide an economic push that provides motivation to resolve technical problems, she says. Regulations, like the UK’s charge on plastic bags, can also help drive important changes in consumer behaviour, Domenech stresses.

Extending responsibility

Recorra is working on more subtle ways to influence people’s behaviour with regards to compostable packaging, Mockridge says. Together with experts from Sheffield University and the environmental charity Hubbub, it is changing the setup of bins at collection sites to help drive down contamination rates. This helps increase the amount of material Recorra can accept for composting.

Mockridge also notes that in October 2025 the UK will introduce Extended Producer Responsibility charges for packaging (pEPR). This could help provide the incentives needed to make compostable products work better. ‘There is scope in the regulations to vary the fees charged to packaging makers to take into account the wider environmental impact of various packaging types as well as basic recyclability,’ he says. ‘The wider environmental impacts will not be used to determine fees in the first iteration of the system next year but are on the agenda for future.’

For Huber, making all plastics recyclable is the best solution, but the many different types available means that is a big challenge. He argues that composting plastics works optimally when they’re mixed with food, such as when used for packaging, containers and cutlery. Yet, as recycling everything isn’t possible, Huber considers incinerating compostable plastics as the best option. He argues that the end products of industrial composting are carbon dioxide, water and heat, the same as incineration. Composting might in fact release more methane, which is a more potent greenhouse gas than carbon dioxide and therefore drives faster global heating. Grady argues that most of the compost locks carbon into soil and plants only temporarily, for around 20 years.

It’s a hopeful sign that scientific knowledge and innovation are seeking to inform policy to make the UK’s compostable packaging situation better. Yet it’s also frustrating that the current situation is so bad. All Binit’s Philippa Roberts wants is a simple answer to the question of whether she can send more compostable plastics to anaerobic digesters. ‘I just wanted to crack on and do something practical,’ she explains. ‘We couldn’t really take data from the manufacturers because, obviously, they always say that it’s suitable for composting and anaerobic digestion.’ If the packaging doesn’t degrade much, that might be beneficial, as dry fibrous material can help make better compost from the digestate, Roberts says. ‘This is a fantastic research project; somebody go find a funding pot and work on it!’

Andy Extance is a science writer based in Exeter, UK

No comments yet