COFs head for the big time

Two decades on from the first reported covalent organic frameworks, Nina Notman investigates what their future holds

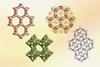

Ten years after creating the first metal–organic framework materials (MOFs), Omar Yaghi’s group succeeded in crystallising the first fully organic structures of this type – constructions that he coined covalent organic frameworks (COFs), due to them being held together by covalent bonds. COFs are composed of light elements such as hydrogen, carbon, boron, nitrogen and oxygen. Yaghi’s group published the first 2D COFs in 2005 and the first 3D versions in 2007. Both contained highly reversible boron–oxygen linkages. Microscopic reversibility is key to enabling crystallisation, as it enables the crystals to be dissolved back to their original building blocks and recrystallised repeatedly until a uniform structure forms.