From metal–organic frameworks to enzymes, Johnson Matthey staff are working to make new discoveries

The question of how science can help deliver a better world is one that scientists across the globe are striving to answer. New innovations in science and technology are helping to answer the most pressing issues essential to humanity’s future. What next-generation materials can be developed that enable cleaner air? How can we create more affordable healthcare? How can innovations help us use our planet’s natural resources more efficiently?

These are some of the difficult questions that Johnson Matthey (JM) seeks to solve by applying its 200 years of experience in science and engineering. As a global leader in developing science that enables a cleaner and healthier world, JM has an established portfolio of technologies and expertise in a range of applications.

Over its history, JM’s science-led approach to innovation and research has yielded multiple discoveries across a range of business areas. Examples include the development and commercialisation of life-changing platinum-based pharmaceuticals cisplatin and carboplatin;1 developing environmentally friendly catalytic converters to improve the quality of the air we breathe; investigating novel solutions for energy storage through next generation battery cathode materials, eLNO; or using catalysts to efficiently produce the industrial chemicals – such as methanol and ammonia - that are essential to modern society.

Yet despite this diverse range of end applications, JM’s core science capabilities lie at the foundation of each. These include materials science and characterisation, chemical synthesis, catalysis and process optimisation – JM’s innovators use this expertise to solve their customers’ complex problems. And there are always new challenges to solve, new discoveries to make and new innovations to uncover. Across JM, innovators set about performing research that will deliver on the promise of a cleaner and healthier world. Here, we offer a deeper dive into different areas of the business to highlight four of the innovators within our company. These young scientists all joined the company within the past five years and truly embody the spirit of Johnson Matthey, in order to deliver scientific research that will impact the wider world.

Creating ‘multi-tool’ materials

Two years ago, Timothy Johnson completed his PhD at the University of Liverpool in the UK investigating metal oxides for photocatalysis. His research, funded by Johnson Matthey, presented him with a clear stepping stone to begin working as a research scientist, and later senior scientist, coordinating research in the development of metal–organic frameworks (MOFs). ‘While the exact materials aren’t identical, there is a lot of overlap between my PhD research and my current role,’ Johnson explains. ‘I’m still researching materials science with a focus on synthesising and characterising materials for specific applications, which is great.’

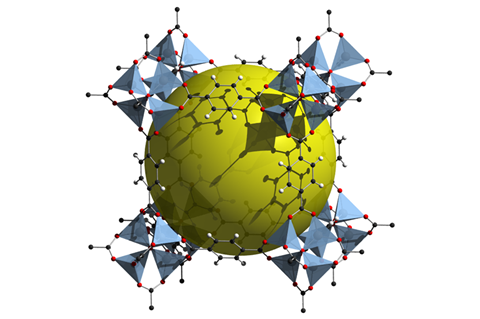

MOFs are a relatively new class of molecule that have garnered considerable attention in both industry and academia. MOFs combine metal ions and organic ligands to create large complex structures. The versatility in the metals and ligands that can be used means that almost infinitely different structures can be conceived and tailor-made to deliver specific properties appropriate for different applications. By choosing the right chemistry, the properties of MOFs, such as geometry and pore size, can be fine-tuned and optimised for a given application.

We’re using MOFs to separate carbon dioxide gas from the waste stream

As a research scientist, Johnson coordinates MOF research from JM’s corporate research centre near Reading, UK, where he and the team synthesise, test and characterise the materials. One of the applications that has gained considerable interest recently is the separation of gases in industrial waste streams to make the processes environmentally cleaner. ‘For an industrial process, you don’t want carbon dioxide to escape due to the environmental impact. We’re using the functionality and sterics of the MOF materials to separate carbon dioxide gas from others in the waste stream,’ Johnson says. In addition to extracting carbon dioxide, research from JM published by Sheena Hindocha and Stephen Poulston has also shown how MOFs can be used to replace activated carbon to adsorb ammonia gases in respiratory filters.2

Beyond applications in clean air, MOFs can also be applied to catalyse reactions. Johnson explains that research is underway to explore the use of MOFs in catalysing the production of active pharmaceutical ingredients (APIs). They found that MOFs offer a framework that can heterogenise homogeneous catalysts, effectively offering the best of both catalyst classes.

Johnson and his team work closely with academics. He explains that collaboration is commonplace at JM and especially so in the field of MOF development. Academic research helps in understanding the fundamental development of MOFs, while industrial research helps apply these learnings to the scale necessary to solve real-world problems. Johnson and his team work to scale production from the low gram scale to the potential multi-kilogram scale while optimising the properties of MOFs to operate at peak efficiency.

Within his team there are three PhD students experiencing both academic and industrial research laboratories. ‘In my role as the project co-ordinator, I aim to help the students to understand some of the needs of the business and how the industry works, all while ensuring the research remains within the focus of the project,’ Johnson says. ‘It’s great to be involved with the next generation of research scientists and novel MOF technologies.’

Using software to support the road to innovation

Following the completion of her PhD in 2013 from Imperial College London in the UK, investigating radioactive isotopes for medical imaging, Hindocha began working at JM as a research scientist before advancing to senior scientist and leading the work on MOF development. In 2016, after three years of laboratory research, she moved to work as a project manager, where she now manages the implementation of a global software tool across JM that oversees new product introduction (NPI).

Taking knowledge from one area of chemistry and applying it to another is where innovative solutions come from

This tool is designed to help JM manage projects across all business areas. As new products are a key component to innovation, having tools in place that manage the pipeline of projects is advantageous, helping to open dialogues and increase awareness and visibility throughout the NPI process. ‘This can be at the front end, where we generate ideas, such as “I have this new idea for a technology” or “This technology could be applied to this market”; through to the specific application and how it helps the customer,’ Hindocha explains. ‘It allows us to better manage the entire portfolio across the whole business and ensures the right decisions are made at the right time.’

‘The connectivity is very interesting to me,’ Hindocha says. ‘Going from a lab where I was focused on one specific avenue of research to then moving into a more overview role was really interesting. You can see all the pieces being pulled together across the different areas of the business.’

Her transitions between academia, her research scientist role and now the project manager position have not fazed Hindocha. ‘For me, being able to develop new things and be innovative in new areas is something I do in all different spaces,’ she says. ‘Taking knowledge from one area of chemistry and applying it to another is where innovative solutions come from, making it hugely valuable. It’s a combination of both the transferable skills obtained from my PhD and the exposure to different people across JM.’

Exploring materials that preserve food for longer

Andrew Cornish is a senior scientist working at JM. He joined the company directly after completing his PhD in 2013 from the University of Nottingham in the UK in organometallic chemistry. ‘My PhD was investigating fundamental chemistry, attempting to create unsupported metal–uranium bonds with potential learnings for uranium clean up,’ he explains. ‘The transition from academia to industry was different but really interesting; shifting from researching fundamentals to a project with much shorter-term product-focused applications.’

Cornish is now applying his expertise to develop new ethylene scavengers that help extend the shelf-life of fresh produce. Ethylene is a hormone released by fruit and vegetables that regulates ageing and ripening processes in certain produce. Its removal from the immediate environment surrounding the produce will often assist in delaying these processes and extend its storability and shelf-life.

We’re helping to do our part to prevent food waste as much as possible

He collaborates with colleagues in another part of JM that develops modified atmosphere packaging (MAP), which regulates the atmospheric gases around fresh produce in order to extend storability and shelf-life. ‘Our technology works in combination with the MAP components and together can help to add weeks or months onto the shelf-life of many produce,’ Cornish says. ‘And we are hoping that we can extend this further through optimisation. In our case, we’re not concentrating on extending the time available to ship food across the world, we’re focused on reducing the amount of food waste.’

Food waste is a major issue across the globe. The Food and Agriculture Organisation of the United Nations estimates that roughly one third of food produced in the world for human consumption is either lost or wasted. Within any shipment of fresh produce, a small percentage will be overripe when it arrives and need to be discarded. ‘By extending the shelf-life within the packaging, we can help reduce this percentage,’ Andrew says. ‘We’re helping to do our part to prevent food waste as much as possible.’

Discovering future enzyme catalysts

When Ahir Pushpanath finished his PhD from Birkbeck, University of London, he wanted to continue using the computational skills he had developed for enzyme analysis in an industrial setting. Joining JM five years ago, he began working in a small biocatalysis team to further develop existing portfolio enzymes for use in industrial chemical transformations. As a result of successfully demonstrating and integrating his computational biology and bioinformatics approaches to the biocatalysis workflow, Pushpanath was made team leader of the enzyme development arm of biocatalysis in July 2017. Together with a multi-disciplinary team that includes molecular biologists, analytical chemists and robotics specialists, he is continuing to discover and develop viable biocatalysts that can be used to catalyse a range of chemical reactions desired by the fine chemicals industry.

Identifying the right enzyme for the right reaction is not a trivial task, owing to the near limitless availability of different enzymes. Currently, large public databases hold information on hundreds of millions of functionally uncharacterised natural enzyme sequences, each with a unique combination of amino acids. ‘This is both the beauty and challenge of working with enzymes,’ Pushpanath explains. ‘We need to identify the most active enzyme amongst the millions of potential sequences.’

We can embrace biology in order to do tomorrow’s chemistry

Identifying the right biocatalyst relies on rationally narrowing the number of possibilities down to a more manageable set of enzyme sequences that are then subsequently screened, preferably using robotic techniques. Pushpanath works to identify enzymes that are described as ‘promiscuous’. This means they can promote reactions beyond their main one, and also display broad substrate scope. The enzyme ‘hits’ identified as potential biocatalysts can also be fine-tuned by mutagenesis to perform the needed synthetic chemical reactions. Identifying these enzymes requires computational algorithms. Hypotheses are formed by the team, based on protein-modelling studies and calculations based on the interaction between the molecule and an active site. They are then used by the algorithm to sift through the known enzymes to identify the sequences that have the desired amino-acid residue prerequisites for efficient catalysis.

‘Using our approach, we can confidently identify, produce and test between 10–15 enzyme sequences from the millions in the database within two months, with a high probability that one enzyme will catalyse the given reaction.’ Pushpanath explains. ‘We then take the best hit and perform further computational testing to maximise their efficiency for the industrial process. All these processes are able to be conducted in one seamless workflow.’

The pharmaceutical industry is increasingly relying on the selective synthesis of chiral molecules, such as chiral amines and alcohols, and biocatalysis offers a highly efficient and selective route to these products. It effectively provides the chiral intermediates to many pharmaceutical ingredients. Furthermore, the synergy between biocatalysis and the rapidly growing area of synthetic biology is a topic that could represent the future of API development.

‘I think our innovations in biocatalysis have really demonstrated the advantages of having an interdisciplinary approach to science research,’ Pushpanath said. ‘We have demonstrated that we can embrace biology in order to do tomorrow’s chemistry.’

Johnson, Hindocha, Cornish and Pushpanath are just four of JM’s innovators working to create the next generation of materials and technologies that provide solutions for our customers and a positive impact on our planet. Innovation and novel discovery lie at the heart of any scientific company, beyond those discussed here. But as well as the right scientific technology, every new discovery needs the right minds offering the right expertise. JM is seeking to solve difficult global challenges by developing the next generation of scientific innovations. By combining novel interdisciplinary research and seeking the next generations of innovators, these challenges can be overcome and new discoveries made.

Liz Rowsell is the R&D director at Johnson Matthey

Note: eLNO is a trademark of the Johnson Matthey group of companies

References

1 C Barnard,Johnson Matthey Technol. Rev., 2017, 61, 52 (DOI: 10.1595/205651317x693624)

2 S Hindocha and S Poulston,Faraday Discuss., 2017, 201, 113 (DOI: 10.1039/c7fd00090a)

No comments yet