Global warming and ocean pollution are among the most publicly discussed topics in society today – and a circular economy relevant to both

Every single day, one million tonnes of plastic is produced worldwide – and that rate is only going to increase. With the majority of that plastic going to landfill, ways to reduce the waste burden and transition to a circular economy – where plastic is recycled many times – are in great demand.

After plastic products have been collected for recycling, they are cleaned and then similar polymers are melted together and new articles are formed. However, not only are there concerns about the decline of polymer quality with each recycle step, but also that additives and impurities cannot be effectively controlled. This can have a serious impact on the safety and potential uses of the recycled material.

Without every partner in the global supply chain aware of what compounds exist in every single component, trust and safety can be lost. Managing that data in a transparent and traceable system of record is critically important, and that is just what a cloud computing solution from Veeva can do for you.

The three major recycling methods are:

- Mechanical (sorting, cleaning, grinding and melting)

- Chemical (dissolve and precipitate polymers)

- Pyrolysis (producing oil and gas that can be used for plastic production)

Over 50% of all plastic recycling is based on mechanical recycling

How is product safety affected?

Product safety is paramount. To ensure safety for humans, animals and the environment, a fast-growing regulatory jungle has emerged. Regulators seek to protect living things from potential – and proven – hazardous substances. These regulations can be international, national, regional and even local – which creates a complex, sometimes conflicting, tapestry of rules that chemical companies must navigate.

For any regulated market, chemical suppliers are obliged to inform manufacturers in their supply chain about substances of concern in their materials. It is a problem for buyers of recycled materials that they may not be informed of the origins of materials they purchase, and which substances of concern might be in the composite.

For example, in the EU, there are currently 205 substances of very high concern (SVHC) listed and it is practically impossible to test every batch of recycled material for all these substances. Therefore, the European Chemicals Agency makes it mandatory for suppliers of articles to notify the agency of any article containing at least 0.1% by weight of a SHVC.

This should help waste and recycle operators to identify material streams that could be contaminated by SVHCs. Notification of these articles – including the article number – will be mandatory after 5 January 2021 in the EU. For example, every o-ring would represent an article, so dismantling complex objects like cars would require detailed knowledge about how to find and recover each of the many individual articles it contains.

Traceability from supply chain to customer

Many people – and even certain media outlets and NGOs – wrongly perceive the chemical industry as a self-governing entity. From this perspective, the ever-growing regulatory framework garners less attention and is even less understood. And often what seems reasonable today will be deemed a risk tomorrow. Chemical companies must be ever-watchful of new regulation and must take these into full consideration when it comes to global supply chain management.

Much of the discussion around closed-loop recycling management and recycling focuses on new technologies, not on the laws and regulations for compliance. With all the existing regulations and the increased obligations to fulfil specific recycling rates, the question becomes: can chemical companies guarantee product safety without knowledge of the entire supply chain?

Vital information cannot be lost on local drives nor time wasted searching for current versions of files

Furthermore, compliance with regulations is often not enough. Modern analysis techniques will show the presence of substances even when far below the limits at which problems occur, which can trigger alarming news reports even without proof of a health risk. The challenge for chemical companies is significant, and they may have thousands of suppliers and customers. Correspondingly, hundreds or even thousands of raw materials must be procured, checked and processed for production.

Finally, chemical companies place thousands – even tens of thousands – of different products on the market. Great agility is needed for chemical suppliers to not only ask the correct questions about the provenance and composition of chemicals, but also to track the answers and ensure this information remains current and correct in a dynamic supply environment. Vital information and documents cannot become lost on local drives, and time cannot be wasted searching for files to establish which version is current.

Using an intranet is no guarantee against losing documents as different users apply different conventions and solutions. Single documents often belong to multiple projects and without associated metadata it can become almost impossible to trace and track project affiliations. And as regulatory requirements increase, the teams of regulatory specialists and product stewards grow to meet the work demand. Those teams need a single source of truth, especially in a global context.

Cloud solutions to manage regulatory information, such as those provided by Veeva, ensure siloed teams access to the same knowledge base, which enables collaboration using system-driven workflows designed around their needs. As chemical companies manage thousands of documents and customer requests annually, a modern digital system in which data and documents are cohesive facilitates the capture of an entire compliance context and history of a chemical again and again.

An efficient cloud solution can ensure that a single source of truth is maintained end-to-end, from supplier to customer

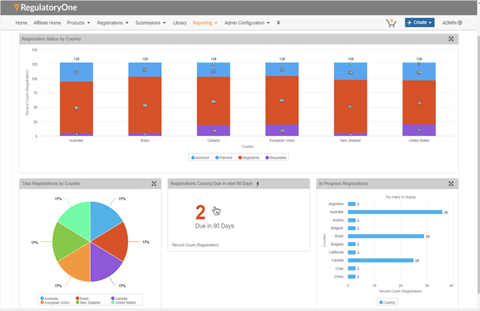

A key part of that compliance assessment is a raw material questionnaire which captures detailed information on a supplied chemical. Managing and assessing this information across a plethora of raw materials in context with dynamic manufacturing is a major pain point, but is essential to accurately understanding real-time product compliance. By combining compliance assessments, documents and decisions in a system of record, a fully transparent and traceable picture emerges. With compliance data and documents housed in one system, key performance indicators, reports and dashboards become intrinsic to the system and available at the push of a button.

Satisfying customers, authorities and the public is key

Many speciality chemical and consumer product companies have made commitments for a closed-loop economy. Technical innovation is an important part of the circular economy of the future, but fulfilling regulatory requirements and meeting the public’s expectations will play an equally important role for the success of each company.

With an efficient and easy-to-use cloud solution in place, regulatory specialists and product stewards can focus on bringing value to their company, rather than putting out fires and endlessly searching for information. They can ensure that a single source of truth is maintained end-to-end, from supplier to customer. If chemical companies can transform the regulatory departments from cost centres to value generators, the path to a fully circular economy becomes easier to traverse.

The author of this article is Shawn Steuer, Veeva’s director of strategy for regulatory in Europe

As a subject matter expert, Steuer brings chemical industry suppliers, manufacturers and consultants together and supports them in all regulatory and quality management challenges

No comments yet