A new process for chemically recycling commercially available polymethacrylates under visible light has been discovered serendipitously by chemists in Switzerland. The researchers demonstrated that the process, which does not require specially designed polymers, could work on commercial samples of plexiglass.

Around 4 million tonnes of poly(methyl methacrylate) (PMMA) are produced every year, for applications ranging from perspex for spectacle lenses to plexiglass for shatterproof windows. Physical recycling degrades the properties of the PMMA, while pyrolysis – the standard chemical recycling method – requires temperatures over 400°C and partially decomposes functional groups before the whole carbon–carbon backbone breaks, which leaves contaminants in the recycled material.

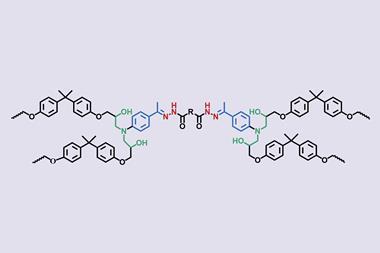

Researchers have synthesised ‘designer’ polymers with pre-installed weak links or end groups that allow the polymer chain to be unzipped under specific conditions. However, most PMMA used commercially doesn’t have these specialised groups, as they tend to compromise the polymer’s stability during use.

Athina Anastasaki and her colleagues at ETH Zurich were investigating the possibility of performing similar chemistry on PMMA without pre-installed end groups. ‘Commercial polymers such as plexiglass do not have a specialised end group, so that meant we could not activate the reaction,’ explains Anastasaki. ‘Our idea was to somehow come up with a way to do multiple activations throughout the backbone so that we could break it down to the monomer from multiple locations. To realise this we had to come up with ways to do a hydrogen atom transfer reaction.’

While attempting to perform the reaction under light using a catalyst, the researchers were puzzled to find that it was occurring in their control experiment in which the catalyst was not present. They eventually worked out that the hydrogen atom transfer was being triggered not by the catalyst but by chlorine radicals released from the 1,2-dichlorobenzene solvent. The researchers confirmed this by showing that it also worked in other chlorinated solvents such as 1,2,4-trichlorobenzene, but not in non-chlorinated solvents.

At 150°C, the researchers achieved full depolymerisation of almost all types of PMMA they tested, regardless of the specific synthesis method and end group, simply by using 415nm LED light. They also achieved successful depolymerisation of various commercial samples of plexiglass, despite the presence of unidentified and variable impurities.

Yutan Getzler at Kenyon College in Ohio, US, is impressed by the chemistry. ‘Within the world of PMMA recycling, I think this is a really significant advance,’ he says. He is concerned, however, about the industrial feasibility of reactions reliant on halogenated solvents, which are usually regulated carcinogens. ‘Probably some of that has to do with the kinds of things we’re seeing here in their proposed mechanism, which is that you can get photo-generated radicals that then go off and do chemistry in ecosystems.’ He also notes that PMMA makes up a tiny fraction of the 400 million tonnes of plastic produced every year, which limits the potential impact the new process could have on the overall problem of plastic waste.

Anastasaki says that the researchers are investigating the possibility of eliminating the chlorinated solvent, but that they have already received interest from several companies seeking to commercialise the process.

References

H S Wang et al, Science, 2025, DOI: 10.1126/science.adr1637

No comments yet