Lithium-ion batteries can hold more energy per unit mass than traditional rechargeable batteries such as nickel–cadmium, allowing portable electronics to be made smaller and lighter and last longer between recharges. But for high-power applications, manufacturers still need higher charge capacities to, for example, give electric cars greater range.

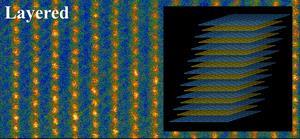

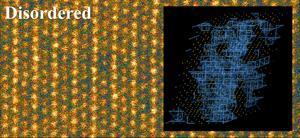

When a lithium-ion battery is discharged lithium ions flow into the cathode and are then driven back to the anode during recharging. Maximising the charge capacity of the battery therefore involves increasing the electrodes ability to store and release lithium. Cathodes are traditionally made of a layered oxide in which lithium ions and transition metal ions sit in separate, well-defined planes. This ordering was thought necessary for efficient operation of the electrode because imperfections cause the oxide structure to contract, making it harder for lithium ions to squeeze in and out.

Gerbrand Ceder and colleagues at the Massachusetts Institute of Technology and Brookhaven National Laboratory studied Li1.211Mo0.467Cr0.3O2 to see if it would make a good cathode. This material has a layered rock salt-like structure, but just a few charge–discharge cycles cause some of the lithium cations to swap places randomly with transition metal ions, leaving the metal ‘cation disordered’. In principle, this should prevent lithium ions from entering or leaving and stop the cathode working. In fact, the material’s capacity remains steady despite the degradation of the structure.Ceder and colleagues used electronic structure modelling to investigate. They found that cation randomisation does inhibit the diffusion of lithium ions in and out of the material, as conventional wisdom predicts. However, if enough lithium is present, seams of lithium ions form between the centre and the outside of the material, allowing lithium to diffuse in and out without passing a transition metal ion. ‘I think that's the most important thing,’ says Ceder, ‘It's not so much the new material but a new direction for looking for cathode materials.’

Materials scientist and engineer Yi Cui at Stanford University, US, is intrigued. ‘This is a very nice piece of work exploring a counter-intuitive materials design principle for high-capacity cathode materials,’ he says. ‘The cathode is the most limiting factor for the energy density of lithium-ion batteries, so the work here is timely in providing a potential new direction to look into.’

No comments yet