Drones are changing the way industry and science operate. Small, manoeuvrable, unmanned aircraft allow access to difficult or dangerous-to-reach sites and equipment, so it isn’t surprising that the chemical industry, as well as fields like atmospheric chemistry and astrochemistry, are investing in them. But what is surprising is the sheer diversity of how they are being applied.

These systems are not very well-defined, with various terms coming in and out of favour over the years, including unmanned aircraft systems (UAS) and, more recently, uncrewed aerial systems. But a drone usually refers to any powered aerial vehicle with no human operator on board that flies autonomously or via remote control.

Joseph Morgan, an expert on robotics and advanced industrial practices, leads a team at Dow. His job is to ensure that the lessons learned in drone operations are shared across the company.

Morgan says that Dow wants to embrace new technologies and use them to generate a competitive advantage, as well as to create a safer environment for employees and contractors. He says drones can accomplish both goals.

‘Many Dow structures are very tall, and often we have to do work that is many feet off the ground – inherently, that’s a dangerous place to put a human,’ he explains. ‘Historically, companies would build scaffolds to access these remote locations but now, as advanced technologies have come around and especially with automation, we’re able to do these jobs without putting people in harm’s way.’

Drones help workers avoid high structures or confined spaces, but there are still significant risks. That’s where Morgan and his team come in. Drones can potentially generate a spark or heat that might trigger a fire or explosion. Many of these crafts are battery-powered quadcopters that have four propellers spinning around at high speed. ‘We got to thinking that there’s a risk in the movement of the air particles,’ Morgan recounts.

To address this, Dow worked with one of its manufacturers to determine the maximum speed of its drones’ propellers. That figure was then used to establish that it was sufficient to generate a spark – simply by air particle movement. ‘That spark, by the way, was above the minimum ignition energy of some of the known chemicals that we produce,’ Morgan notes.

‘That just reaffirms that if you were to put a drone into a piece of equipment that was not properly prepared for inspection by drone then we could be introducing a source of heat or a spark that we would not have known about,’ he says. ‘This was an unexpected issue that we did not know about, but now we do, and we build our programme around that to mitigate those risks.’ Other issues include plastics or metals in the drone that might react with certain chemicals in a dangerous manner.

Therefore, to prevent such issues, he and his colleagues ensure that equipment and facilities are correctly prepared and cleaned before they place a drone anywhere in a Dow plant.

Chemical companies have various options for cleaning their equipment, one of which is hydroblasting – pressure washing at 40,000psi rather than the 5000psi used by domestic systems. ‘You can imagine the inherent dangers of that, which are well-known across the industry, and so my team and I look for safer ways of doing this kind of work,’ Morgan says.

Not only is Dow using robotics for such cleaning operations, the company also employs such technology to check the condition of its facilities. Drones can be flown right up to a piece of equipment to take ultrasonic thickness readings. ‘From that thickness, we can then estimate the remaining time that that equipment is expected to be in service before it requires some kind of repair or replacement,’ Morgan explains. ‘That’s kind of at the leading edge of what drones are doing in the plants.’

Droning on in research

It’s not just industry that wants in on the action, scientists are taking drones seriously as a research tool. A team at Princeton University has been using them to identify large and small methane leaks at natural gas facilities. The researchers say their new approach can accurately identify and quantify methane leaks up to 25 times smaller than those typically detected using other available methods. They note that it can even pinpoint the emissions source to within a metre.

The team’s small drone is equipped with a retroreflector – a type of mirror that reflects incoming light back at its source like cat’s eyes on a road. A base station controls the drone and contains all the bulky gas sensing equipment, meaning the drone is not weighed down with equipment and so can stay aloft for much longer. A laser is used by the base station to measure the dispersion of light from the retroreflector in the air surrounding the drone and interpreted using spectroscopy. Changes in the composition of the air, such as by the addition of methane, allow leaks to be both located and quantified.

Current drone-based technologies for atmospheric sensing typically require a large and expensive gas sensor. ‘We need bigger, heavier drones to carry these bigger, heavier sensors, and if you can lower the weight and size of a package on a drone then you can fly for longer – so there are many incentives pushing for smaller and lighter,’ says Princeton atmospheric chemist Mark Zondlo, one of the study’s co-authors.

In their proof-of-concept study, Zondlo and his colleagues were looking at methane, but he says there is no reason why many wavelengths of light couldn’t be combined for the lasers so that multiple species can be detected, like carbon dioxide or ammonia, alongside methane.

The next step for the Princeton team is to test and validate its system in a real-world setting. Zondlo expects they will be flying their modified drone around local dairy farms later this summer.

‘Atmospheric sampling is very difficult on a farm with a car, or even on foot, because you would have to be climbing over fences and avoiding other things,’ Zondlo notes. ‘You can’t walk through a lagoon, you can’t walk through an aeration tank at a wastewater treatment plant, you can’t walk through a smokestack,’ he adds. But drones allow for 3D sampling of the atmosphere without such restrictions.

Even if drones aren’t allowed to enter a particular site, they can fly around and sample the perimeter of an area. ‘They’re small, lightweight, easily manoeuvrable and have much more flexibility – it’s a very nimble sampling platform,’ Zondlo says.

Down in the depths

Drones are also being employed by researchers deep below the ocean’s surface. Scientists at the University of Alaska Fairbanks (UAF) have worked with international commercial partners to develop the autonomous drone Seaglider to measure ocean acidification.

Until now, data on ocean acidification was measured using either stationary sensors or ships performing sampling transects. This has meant that significant areas of the ocean go unsampled, especially during the winter when conditions are dangerous for research vessels. But the UAF team, collaborating with several of its industrial partners, redesigned an existing underwater sensor that measures carbon dioxide and integrated it with Seaglider.

It was designed and built by the University of Washington in Seattle’s Applied Physics Laboratory in 2018 and it can dive up to 1km below the surface to conduct weekslong all weather missions in remote parts of the ocean all year round. However, incorporating the carbon dioxide sensor was no simple task as the size of the sensor changed the buoyancy of the craft.

‘It took a lot of thought and so many different trials, and we’re still working on making the glider more stable,’ says project leader Claudine Hauri, a chemical oceanographer with UAF’s International Arctic Research Center. ‘We had to actually put in an extension because the sensor otherwise wouldn’t fit in the glider,’ she recalls. ‘It took many iterations to get where we are right now and we’re still constantly, after every mission, figuring out what we need to improve.’

Last spring, the researchers deployed their latest version of Seaglider in the Gulf of Alaska. The inorganic carbon chemistry of the gulf is unique because of the significant amount of freshwater from glaciers that are draining into it. The currents and weather also make oceanographic work in the gulf challenging so there is a significant data void that the glider can help fill, Hauri says.

The UAF team has also integrated a methane sensor into its Seaglider. The scientists hope to track methane releases from oil and gas operations, thawing permafrost and destabilising methane hydrates that all contribute to climate change.

Pending new funding, Hauri says the team plans to develop a glider with simultaneous sensing capabilities for several chemical species and environmental conditions. These include pH, conductivity and chlorophyll a, as well as dissolved organic matter.

Come fly with me on strange new worlds

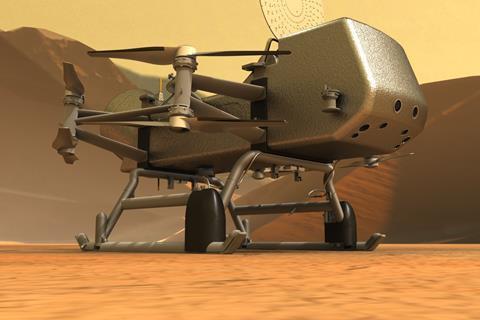

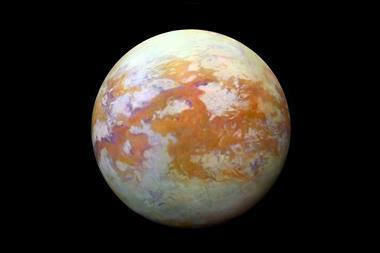

Elsewhere in our solar system, Nasa’s forthcoming Dragonfly mission will send a 16-bladed drone to the surface of Saturn’s icy moon Titan. Slated to launch in 2027, Dragonfly is expected to arrive around 2034 and help elucidate Titan’s chemistry.

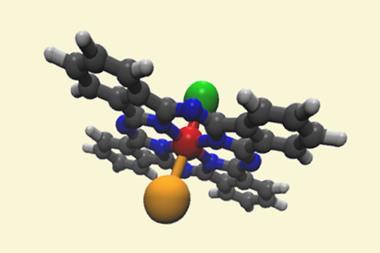

Nasa’s drone will take samples from sites of interest around the moon back to the lander. There they will be irradiated by an onboard laser or vaporised in an oven and fed into the Dragonfly Mass Spectrometer (DraMS). This will enable scientists to study the chemical makeup of Titan’s surface remotely.

It is hoped that the Dragonfly mission will shed light on what sorts of chemical conditions existed on Earth to spawn the prebiotic chemistry that enabled life. According to Nasa: ‘Titan’s abundant, complex, carbon-rich chemistry, interior ocean and past presence of liquid water on the surface make it a perfect place to study these things and the potential habitability of an extraterrestrial environment.’

Melissa Trainer, a planetary scientist and astrobiologist, and one of the Dragonfly mission’s deputy principal investigators, explained that DraMS is designed to look at the organic molecules that may be present on Titan, as well as their distribution in different environments on the moon.

Other equipment that will be aboard the Dragonfly drone include a γ-ray and neutron spectrometer for elemental analysis of the ground beneath the lander, as well as an imaging microscope.

Ralph Lorenz, a planetary scientist at the Johns Hopkins Applied Physics Laboratory in Maryland and Dragonfly’s mission architect, emphasies that Titan is very chemically rich. ‘There are special places on Titan where some really interesting prebiotic chemistry may exist – we expect a lot of photochemical material on the surface, but there’s also the big question of how complicated the chemistry can get,’ he says. Lorenz and his team are particularly interested whether there are chemical systems there that replicate some of the functions associated with life such as metabolism, information storage and replication. Lab tests have suggested that conditions on Titan could support the formation of organics such as DNA bases and amino acids.

As there are areas on Titan that are difficult to negotiate with a wheeled vehicle like a rover, Lorenz notes, a drone is the ideal way to get around. And, because Titan’s gravity is similar to that of the Earth’s moon and also has a very dense atmosphere, aerial mobility is much easier there than almost anywhere else in the solar system, he adds.

The rise of drones across numerous sectors in recent years owes much to decreasing costs and, importantly, significant technical advances. Experts agree that trying to imagine or foresee the features and capabilities of future drones, and how they might revolutionise the sciences, is tricky at best. ‘The sky is the limit,’ Dow's Morgan declares. ‘It’s only a compromise of size, weight, thrust, battery life, and control.’

No comments yet