Drug precursor made by solar-powered cyborg yeast

Indium phosphide nanoparticles supply electrons for shikimic acid synthesis

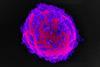

Scientists have augmented a genetically modified version of brewer’s yeast with semiconductor crystals so that its biochemical processes concentrate on making shikimic acid, a precursor for the antiviral drug Tamiflu.

Neel Joshi’s team at Harvard University engineered a strain of yeast that overexpresses the genes involved in shikimic acid synthesis, and a attached indium phosphide nanoparticles to the cell surfaces. The nanoparticles act like tiny solar panels – when illuminated, they generate electrons that can be used by the yeast in the pathway for producing shikimic acid.