Researchers in the US have designed an approach that can generate ammonia from water contaminated with nitrate.1 It combines the nitrate reduction reaction with Donnan dialysis to show how a troublesome pollutant can be transformed into a valuable product.

Aqueous nitrate frequently enters water supplies when fertiliser byproducts are washed into aquifers and waterways. This can exacerbate algae growth and cause algal blooms, with some forms – for instance blue-green algae – being harmful to human and animal health.

‘There is so much wastewater emitted in the world, but then there’s so much value in that wastewater that can be recovered,’ says Dean Miller from Stanford University. This notion has spurred an increasing number of researchers to develop electrochemical methods for recovering specific products – such as nitrate – from wastewater.

The value of recovering nitrate from wastewater is two-fold. Firstly, it removes a contaminant from the water. And secondly, by converting the nitrate into ammonia it creates a supply of this valuable chemical by a greener method than the traditional Haber–Bosch process.

Recovering nitrate from wastewater, however, is complicated because real wastewater contains so many different contaminants. Moreover, the synthetic solutions typically used to test nitrate reduction reaction electrocatalysts contain nitrate in higher concentrations than would be found in real life – not all electrocatalysts will have the same efficacy with more dilute samples.

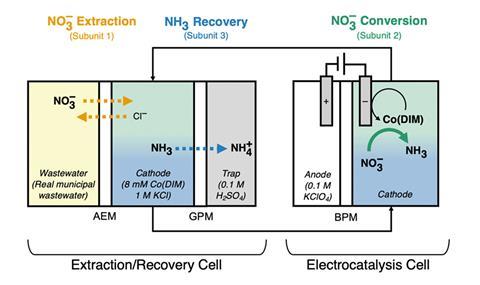

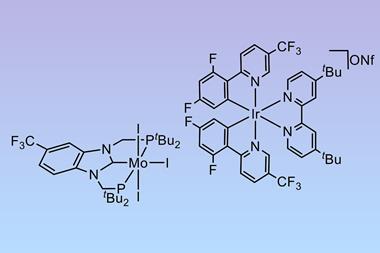

Miller and colleagues have designed an electrocatalytic system to produce ammonia from wastewater that can cope with the impurities and low nitrate concentration found in real wastewater. It uses the known nitrate reduction catalyst Co(DIM) – where DIM is 2,3-dimethyl-1,4,8,11-tetraazacyclotetradeca-1,3-diene – alongside Donnan membrane dialysis, a low-energy extraction method that removes contaminants from wastewater.2,3 The result is a single low-energy unit – which they call Electrocatalyst-in-a-box – that performs three processes: it extracts nitrate, converts that nitrate to ammonia then recovers the ammonia as ammonium sulfate.

‘Because a lot of the wastewater that is emitting nitrogen in the first place is coming from agriculture, we’re creating sort of a circular environment for which we can recycle nutrients back to the place that discharged the pollutant in the first place,’ explains Miller.

The team has ‘engineered a way to use homogeneous molecular catalysts for wastewater treatment that avoids introducing the catalyst into the wastewater. By first separating the nitrate from the wastewater using Donnan membrane dialysis, they have overcome the issue of potentially introducing a toxic substance into the environment,’ comments Elizabeth Corson, an expert in converting waste products into valuable chemicals based at the University of Kansas in the US. ‘This enables them to design molecular catalysts and electrolyte conditions that optimise ammonia production without concern for water contamination. ‘

‘[The] Electrocatalyst-in-a-box concept opens up the use of homogeneous molecular catalysts for all types of electrochemical wastewater treatment and resource recovery,’ Corson adds. Indeed, Miller says the approach could be adapted to selectively extract any ionic component – for example to remove sulfates and recover them as sulfuric acid.

With a patent application in progress, future studies into Electrocatalyst-in-a-box will include converting it to continuous operation mode, optimising its scalability and investigating any potential failure mechanisms for long-term operation.

References

1 D M Miller et al, Energy Environ. Sci., 2024, DOI: 10.1039/d4ee01727g

2 M J Liu, D M Miller and W A Tarpeh, Environ. Sci. Technol. Lett., 2023, 10, 458 (DOI: 10.1021/acs.estlett.3c00205)

3 H Chen et al, Chem. Eng. J., 2023, 455, 140522 (DOI: 10.1016/j.cej.2022.140522)

No comments yet