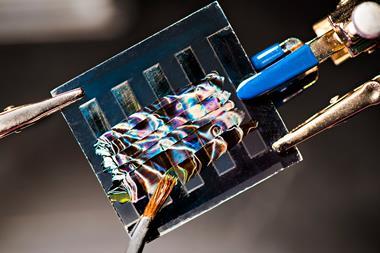

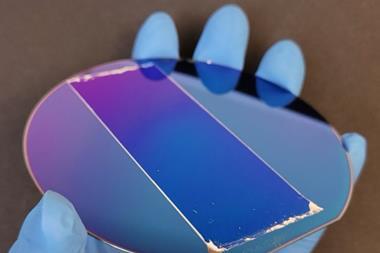

A new roll-to-roll system that can print perovskite solar cells could streamline the scale-up of the technology. ‘It marks a pivotal milestone in the field, showcasing the potential for the cost-effective production of high-performance solar cells,’ says lead author Doojin Vak from CSIRO Manufacturing in Victoria, Australia. ‘This breakthrough suggests the possibility of producing large-scale perovskite solar modules that could match … even surpass the performance of commercially available silicon [alternatives],’ he adds.

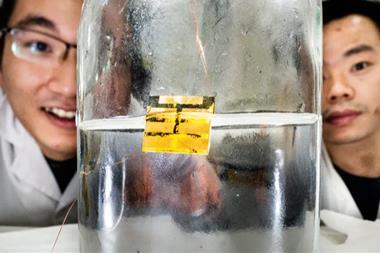

Roll-to-roll production had already been identified as a promising process for the manufacture of perovskite solar cells, explains Vak. However, hurdles such as depositing the perovskite solutions on continuously sliding substrates, as well as time and temperature constraints, limited the industrial implementations. ‘Our team demonstrated the roll-to-roll production of series-connected [solar] modules for the first time and achieved a significant increase in the record efficiency of solution-processed solar cells,’ he adds. Producing a roll-to-roll perovskite solar module using this technology took two researchers two days.

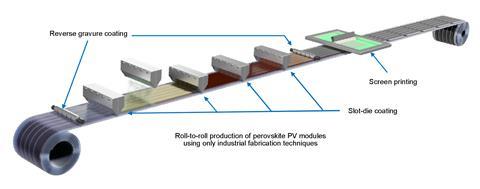

The roll-to-roll systems are widespread in manufacturing and printing, and Vak says that it’s a ‘proven method for mass-producing low-cost [printed] products’. It works like ‘a larger version of a cassette tape with multiple printing heads in the middle’.

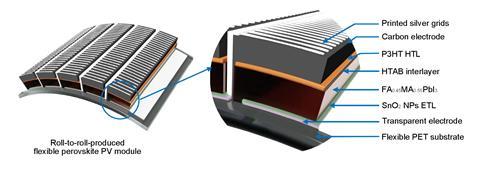

‘Roll-to-roll printing involves the continuous deposition of materials on a flexible substrate as it moves through a series of rollers,’ explains Annalisa Bruno, an expert in perovskite solar cells at the Energy Research Institute at Nanyang Technological University, Singapore. ‘In this case, the perovskite layers and other components are printed onto the substrate sequentially,’ she explains. At this stage, the main challenge is to ensure that each layer dries and settles completely before the next layer is deposited. The development of different inks facilitated the process, according to Bruno. Researchers developed ‘appropriate ink compositions [to] optimise the morphology [and] improve the drying process of each layer’. They printed all the interlayers, including the components for electron and hole transport and both the carbon and silver electrodes, she explains. Overall, this ‘streamlined scalability, to [reach] low costs and high throughput production’.

Jovana Milić, a perovskite expert at the Adolphe Merkle Institute in Fribourg, Switzerland, agrees: ‘The success of this approach could be attributed to the perovskite-friendly carbon inks and an automated roll-to-roll tester.’ Commonly, the production of perovskite solar cells involved solution processing at laboratory scale, ‘with techniques such as spin-coating … fundamentally incompatible with large-scale device fabrication’, explains Milić. Although ‘it’s a misconception that … perovskites require inert conditions for their preparation’, it’s a ‘breakthrough to demonstrate the full roll-to-roll fabrication of solar cell modules with superior performances under ambient conditions’, she adds.

‘The roll-to-roll printed perovskite cells exhibit efficiencies of up to 15.5% for small-area [devices] and 11% for large-area modules,’ says Bruno. Both figures improve the previous efficiency record for roll-to-roll perovskites of 10.8%. With these parameters, the predicted cost could come in at 70 cents (55p) per watt. ‘While [still] more expensive than silicon, the roll-to-roll breakthrough signifies a significant step toward cost reduction,’ she adds. Moreover, easier production processes could cut carbon dioxide emissions, especially as the roll-to-roll printing works at room temperature.

Another drawback of perovskite solar cells is the potential leakage of toxic lead salts into the environment. Vak argues that when they seal the structure to protect the perovskite from moisture and oxygen this would also ‘prevent lead leakage’. ‘If oxygen cannot come in, lead cannot escape,’ he says. Nevertheless, the team is aware of current concern around the deployment of perovskite cells, especially in cases of complications with the devices and disposal of degraded panels. ‘Our commitment is to find effective ways to ensure the safe use of this technology and we are focused on implementing robust sealing mechanisms and comprehensive [sustainability] assessments to mitigate any potential risks,’ concludes Vak.

References

HC Weerasinghe et al, Nat. Commun., 2024, 15, 1656 (DOI: 10.1038/s41467-024-46016-1)

No comments yet