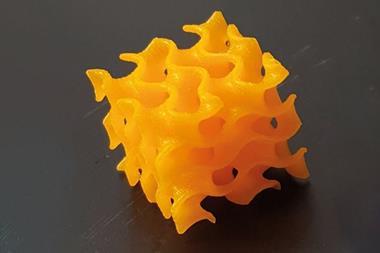

Researchers in China have developed a way to create intricate three-dimensional structures out of glass by mimicking the ancient art of origami.

Glass’ transparency, abrasion resistance and stability make it an extremely useful material, but traditional production methods either require harsh conditions or severely limit the complexity of structures that can be created. Now, researchers have developed a technique that can produce complex glass structures at a low temperature.

The technique involves curing a silica nanoparticle-filled liquid precursor into a polymer composite sheet, which is cut into the desired shape. The flexible sheet is then manually folded at room temperature into a 3D structure, just as is done with paper in origami. Once the structure is complete, the material undergoes pyrolysis and sintering to remove the polymer binder and convert the remaining material into glass.

Although this technique currently relies on manual folding of the polymer composite, the team hopes that the process could be automated. As the cutting process is done using a low-power, digitally controlled laser, the technique may be suitable for large-scale manufacturing.

References

Y Xu et al, Nat. Commun., 2021, 12, 4261 (DOI: 10.1038/s41467-021-24559-x)

No comments yet