Discovery could help save energy and money, but still needs to overcome limitations in humid conditions

A method that reduces friction between two surfaces to almost zero on macroscopic scales has been demonstrated by US researchers. The phenomenon combines nanodiamonds with sheets of graphene, which curl around the nanodiamonds to form ‘nanoscrolls’ that lubricate the two surfaces. As friction wastes so much energy in all sorts of mechanical devices this discovery has huge potential to save both energy and money.

On the macroscale, friction is the result of microscopic imperfections in surfaces, but atomic-scale friction concerns the attractive forces between individual atoms. This opens up the phenomenon of structural lubricity, where the difference in atomic spacing between two surfaces makes it impossible for multiple atoms in one surface to get close to atoms in the other, leading to extraordinarily low friction. However, scaling this up has proven difficult, as macroscopic surfaces are not perfect single crystals with constant lattice separations, but instead are dotted with deformations and grain boundaries that can stick.

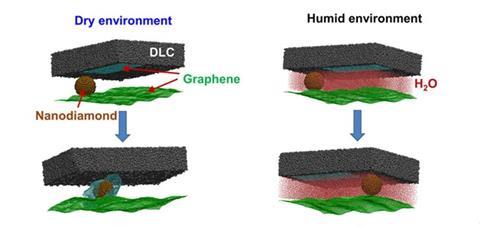

Anirudha Sumant and colleagues at Argonne National Laboratory in Illinois suspected that the surface of diamond-like carbon (DLC), whichconsists of randomly mixed sp3 and sp2 bonds, might provide a perfect lattice mismatch against which graphene could slide with minimal resistance. To test this they passed a millimetre-scale DLC slider across a silica surface covered with graphene. However, the friction they measured between the two surfaces was inconsistent – sometimes very low, other times higher. When they examined wear on the slider, they discovered that nanoscale scrolls of graphene had detached from the graphene surface. Suspecting these were behind the low friction, they added nanodiamonds to the surface to act like tiny ball bearings. When they tested the two surfaces again they found that friction dropped to virtually zero and stayed low as the slider moved. They showed that the graphene flakes bond to and wrap around the nanodiamonds, cutting friction through a mixture of lattice mismatch effects and acting like miniature ball bearings. ‘Once you have this roll then [the DLC] just slides across the surface,’ says Sumant.

Martin Dienwiebel of Karlsruhe Institute of Technology in Germany is impressed. ‘It’s stunning that they observe these kinds of low frictional forces with a system of graphene and diamond, so it’s very interesting and important,’ he says. ‘I would have been a little concerned about this idea that the graphene patches are being rolled around the diamonds, but when you look at the transmission electron micrographs, that’s convincing.’

At present the technique only works in dry, inert conditions, as the oxygen in water droplets can bond to graphene and stop nanoscrolls forming. The researchers are now working on ways to overcome this problem, but Sumant says that, even now, the technique could be useful for many applications, such as space technology or electronic systems where the environment can be controlled. ‘If the benefits are so huge,’ he says, ‘you can imagine putting a container around something and filling it with nitrogen or argon.’

Correction: The story was updated on 18 May 2015 to reflect the fact that this discovery was not serendipitous.

No comments yet