Hydroxide-loaded sponge soaks up atmospheric carbon dioxide

Low-cost charcoal absorbs carbon dioxide and rapidly releases it in energy-efficient process

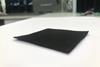

Charcoal ‘sponges’ that are charged with hydroxide ions offer a low-cost, energy-efficient way to capture carbon dioxide directly from air. The researchers behind the finding decided to explore activated carbon because it is ‘cheap, stable and made at scale’. The material’s electrical conductivity also permits a rapid release of captured carbon dioxide, allowing the charcoal-based sorbent to easily be reused.