Layered material displays strength of ceramic with toughness of metal

Lattice-matching prevents brittleness usually associated with ceramics

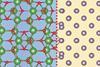

A new technique allows ceramics to become more ductile without losing their strength. It involves the controlled growth of a metal layer on the ceramic surface, which allows its structure to rearrange under stress rather than failing. The researchers behind the work suggest that the method could allow ceramics to be used in biomedical and aerospace applications for which they are currently ill-suited.