Origami boxes capture and release yeast cell using energy from a magnetic field

A tiny robot that can capture a single cell has been made by scientists in the US. The microbot is made of metal-coated plastic cubes, which allow it to open and close using magnetic energy.

Microrobotic devices could one day perform surgery in places where large instruments can’t reach, like inside the smallest blood vessels. ‘[It] is one of the dreams in translational medicine, to assemble microsurgeons in vivo,’ says microrobot researcher Mahmut Selman Sakar from the Swiss Federal Institute of Technology in Lausanne, who wasn’t involved in the study.

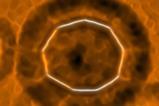

While the team led by Gabriel López from Duke University and Orlin Velev from North Carolina State University has not yet achieved this, their modular microbots are already agile enough to trap a 4μm yeast cell, move and then release it again. Made out of individual polymer cubes coated on one side with metallic cobalt, the microbots store energy from an external magnetic field and release it when the field is switched off.

‘The cube shape means that you can have two different configurations – two cubes have their coating either on the same [AA] or on opposite [AB] sides,’ explains Velev. Depending on the cubes’ sequence, the microbot can carry out different tasks – an ABBA bot, for example, is the simplest grabber. It opens when a magnetic field is applied and closes when the field is switched off. The field’s gradient and orientation then control the bot’s movement and rotation.

In the future, the microbots could do more than simply trap objects. ‘We now have a microtool to investigate mechanical properties on the microscale,’ Velev says. His team has started investigating liquid crystals, using the grabber to squeeze them and establish microscale mechanical forces.

Sakar suggests that the microbots could find applications in microfluidics: ‘You could inject microscale particles into a microchannel and then, using external magnetic fields, bring them together and make a little rotor-shaped object, and spin it to create a fluidic flow for mixing – mixing is a hard task at small scale due to low Reynolds number.’

Currently, Velev and López make each microbot by adding one cube at a time. Velev suggests that templating – using a functionalised surface to direct the cubes into place – could speed up fabrication. Eventually, microbots might even be able to replicate on their own. ‘Right now, we have to design and build every single tool ourselves,’ says Sakar, ‘but it would be fascinating if the tools could then build more tools by themselves.’

References

K Han et al, Sci. Adv., 2017, 8, e1701108 (DOI: 10.1126/sciadv.1701108)

No comments yet