Researchers have demonstrated how mechanochemistry can be used to extract edible proteins from moor grass, a common grass species in the UK. ‘What excites me is that we show that grass can be used to produce the building blocks for food,’ says Bernardo Castro-Dominguez, from the University of Bath, UK, who co-led the work .

With a growing global population and dietary intake changes, there is a need to source edible proteins using alternative and sustainable methods. Previous studies report edible protein extraction from grasses however ‘a lot of the conventional methods use very harsh solvents or chemicals to break down the cell walls’ explains Castro-Dominguez. While these methods are often effective, ‘once you put vitamins and proteins under these harsh conditions, they tend to degrade’ he says. ‘We want to have proteins that are completely in good shape for human consumption.’

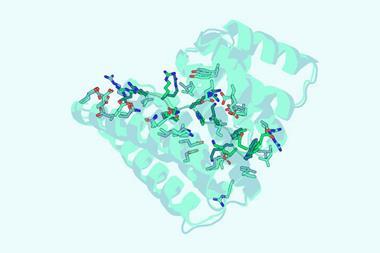

Now, Castro-Dominguez and colleagues have developed a sodium carbonate-assisted grinding technique to extract nutrient-rich protein fractions from moor grass. ‘Imagine the grinding of a pestle and mortar to mechanically break, instead of chemically break, the grass structure and be able to recover the goodies that are within the grass,’ he explains.

Benu Adhikari, an expert in food engineering from the University of Queensland in Australia, says Castro-Dominguez’s team has done a nice job: ‘They have proposed, with evidence, a milder and better technology of extraction of protein.’

Analysis of the amino acids in the protein fractions showed potential applications for different food products. For example, the samples had elevated glutamic acid levels, the amino acid associated with an umami flavour. They also found the amino acid profiles were comparable to soy or oat protein, which suggests they could replace them without compromising nutritional benefits.

Studying the fraction’s thermal stabilities showed that, compared to conventional alkaline extraction, the mechanochemical method ‘leaves the chains a little longer or in better shape, that enables them to withstand a higher temperature, which could favour its use for baking processes’ explains Castro-Dominguez.

Nonetheless, we are a while off sourcing our next meal using grass found in the nearest field. ‘A whole lot of studies need to be done, especially on safety aspects,’ comments Adhikari. He says it is ‘too early to say’ how this study will impact sustainable food industries, but ‘this is definitely nice work and out-of-the-box, and deserves recognition from the scientific angle.’

‘Something we are working on at the moment is the techno-economics of the process. We are also trying to figure out whether people are willing to eat grass-based proteins, or grass-based food,’ says Castro-Dominguez. The team is now looking for ways to remove the recognisable colour and aroma of the grass to help with this.

‘Here we have demonstrated the production of protein, but there are quite a few sugars that we also have in our smoothie of grass. And those sugars can be used,’ adds Castro-Dominguez. ‘Obviously, that requires quite a few steps going forwards, but that’s where we’re moving towards.’

References

This article is open access

O A Olalere et al, RSC Mechanochem., 2024, 1, 375 (DOI: 10.1039/d4mr00016a)

No comments yet