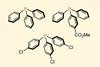

‘Mechanochemistry strikes again’ – this time for deoxygenating phosphine oxides

Mechanochemical process works in 30 minutes under air to regenerate phosphine reagents

Mechanochemistry can regenerate phosphine oxide waste into phosphine reagents by deoxygenating it under air, new research shows. ‘This method circumvents the need for hazardous organic solvents … and does not require complicated synthetic procedures involving inert gases,’ notes Koji Kubota from Hokkaido University in Japan, who co-led the study with Hajime Ito.