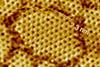

Microscopy unveils piece-by-piece formation of 2D covalent polymers

New results provide ‘fundamental insights’ on the growth of covalent organic framework monolayers

Using scanning tunnelling microscopy (STM), researchers have observed the piece-by-piece formation of 2D dynamic covalent polymers – the basic building blocks to covalent organic frameworks (COFs). These detailed images will help understand complex mechanisms, potentially paving the way to tailored synthetic stacked structures.