Process could cut transportation costs and save farmers money

Scientists in the US have developed a hydrothermal process to turn local rocks into cheap and effective fertiliser.

Feeding the world’s ever-growing population is an urgent global challenge. Fertilisers provide key soil nutrients, like potassium, nitrogen and phosphorus, improving crop yields and food production. Farmers all over the globe use potassium (potash) fertilisers, typically KCl, which manufacturers mine from an ore called slyvinite. Three countries mine the majority of potash: Canada, Russia and Belarus.

Thousands of miles from these potash sources, in the southern hemisphere, lies Brazil. Brazil has huge swathes of agricultural land and is a major corn and soy producer, as well as a big meat exporter, particularly to China. However, the soil is poor quality. As a result, Brazil imports huge amounts of potash fertiliser and 90% of this makes the lengthy, complex and expensive trip from Saskatchewan in Canada. So, the hunt is on for local, cheap and sustainable potassium sources.

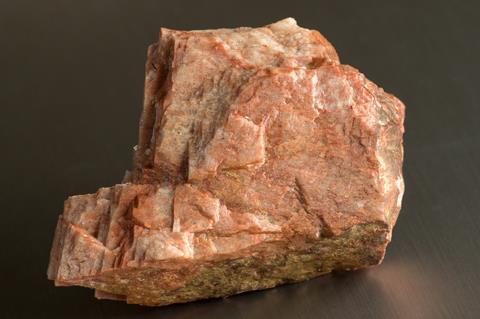

A team at the Massachusetts Institute of Technology (MIT), inspired by the farming situation in Brazil, started looking for abundant sources of potassium. They came across potassium feldspar, a common mineral that makes up the majority of a rock called ultrapotassic syenite. Ultrapotassic syenite is a crystalline rock, similar in appearance to granite, that makes up around 12% of the Earth’s crust. It is found across the globe, including in Brazil, and is also easy to mine. However, potassium feldspars were previously thought to be unreactive, making them poor fertilisers.

Now, with fairly mild chemical processing that MIT’s Davide Ciceri describes as ‘accelerated weathering in an autoclave’, Ciceri and his colleagues think they can change this. Their processing method removes the need for costly and energy- and water-intensive separation and recrystallisation processes, explains fellow team member Antione Allanore. First, they combined syenite and Ca(OH)2 in a steel ball mill. Then they used an autoclave to hydrothermally heat the powder at 200°C for 5 hours. They dried the resulting slurry overnight in a laboratory oven, and then crushed the solid cake using an agate mortar and pestle. Altered feldspar makes up the majority of the final hydrothermal material. ‘Everything that came into the process will end up in the product, in a form that is suitable for the performance we are looking at,’ Allanore adds.

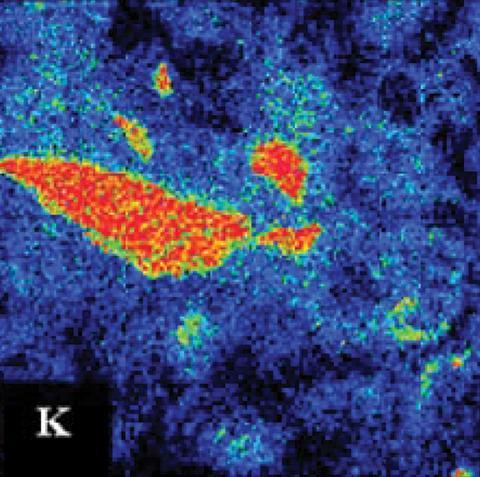

Leaching tests show that potassium is now available in the final product, along with other micronutrients. Potassium feldspar is cheap to mine, has lower associated transportation costs and is greener to process, so Allanore and Ciceri believe their method will significantly benefit Brazilian farmers.

David Manning, a fertiliser expert at Newcastle University, UK, describes the hydrothermal alteration process as a new way of solving a very old problem. The hydrothermal material, he says, ‘seems particularly well suited to tropical soils – where need is greatest.’

The team’s alkaline hydrothermal alteration, also occurs naturally in some geological environments, says Ciceri. Industry already uses similar processes, for example the Bayer process that refines bauxite into alumina. This makes the group optimistic that their process will work on other potassium resources.

References

This paper is free to access until 20 November 2017

D Ciceri, M de Oliveira and A Allanore, Green Chem., 2017, DOI: 10.1039/c7gc02633a

No comments yet