Researchers in Japan have created gold clay that can be sculpted into 3D structures that retain their shape even at high temperatures.

Synthetic clays are surprisingly hard to make. Most natural clays consist of 2D silicate particles, roughly 2µm across and hexagonal in shape. These particles mesh together and attractive forces help to hold them in place – meaning they can be sculpted into 3D macrostructures that can hold their shape even when heated and dried. But in the lab, it takes a high level of structural control to produce particles that are just the right size and shape to stack together and form free-standing 3D structures.

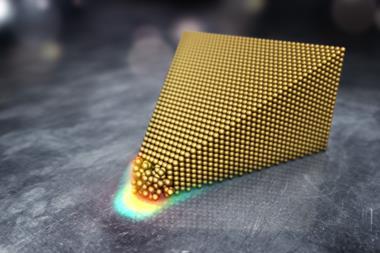

Now, researchers have found a way to make gold nanoparticles that are sufficiently uniform in shape and size to interlace and form a mouldable material. The particles are single-crystal gold nanosheets, grown in a controlled manner between membranes of succinic acid surfactants.

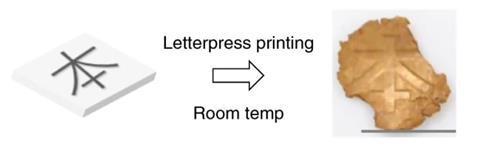

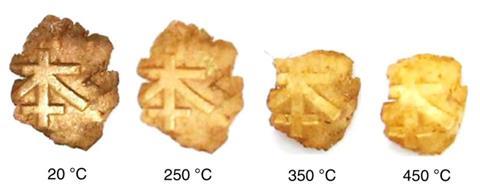

The mouldable gold can be sculpted into free-standing metallic structures, which its creators demonstrated by using casts to press the clay into a flower and a Japanese Kanji character.

The scientists who created the gold clay suggest that it could have uses in flexible electronics, sensors, decoration and the production of thin metal foils.

References

Y Yue and Y Norikane, Nat. Commun., 2020, DOI: 10.1038/s41467-019-14260-5

No comments yet