Tiny nanodiamonds could be used to reinforce biodegradable polymers used in surgical screws that dissolve once their purpose is served

Phillip Broadwith/Boston,US

Using tiny diamonds to reinforce biodegradable polymers could make them strong enough to make surgical screws that simply dissolve once their purpose is served, say US scientists.

Speaking at the Materials Research Society conference in Boston, US, Ioannis Neitzel, part of a team led by Yury Gogotsi at Drexel University in Philadelphia, explained that nanodiamonds would be ideal for reinforcing polymers for biological use because they are completely biocompatible and don’t interfere with cellular processes.

However, Neitzel points out that it is not as simple as just mixing the diamonds with your polymer of choice - the key is matching the surface chemistry of the diamonds to the properties of the polymer. Without any modification, nanodiamonds tend to clump together in the polymer, he says, ’so then when you pull on them you just break the agglomerates apart and you don’t get the advantages of the diamond properties.’

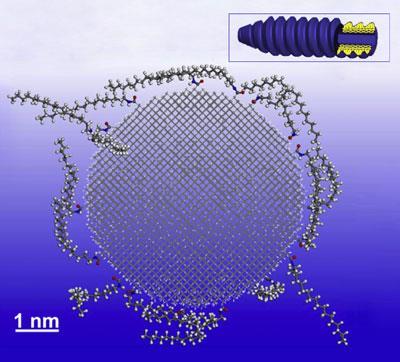

To avoid this, the team took advantage of the fact that the surface of nanodiamonds is covered with functional handles like carboxylate groups. By converting these to amides with octadecylamine, the team produced nanodiamonds with a hydrophobic surface, to match the hydrophobic poly(l-lactic acid) (PLLA) they wanted to reinforce. PLLA has good biocompatibility and biodegradability characteristics, but on its own it doesn’t have the mechanical strength to be used in biomedical applications like surgical screws or bone scaffolds.

’Because you have the hydrophobic chains on the nanodiamond and the hydrophobic polymer matrix, the chains mix together like spaghetti, which helps to disperse the diamonds,’ explains Neitzel. ’It also gives a strong interaction with the polymer, which improves the mechanical properties.’

With 10 per cent added nanodiamonds, the team’s composites are three times as stiff and nine times as hard as pure PLLA, which makes them much more suitable for making things like surgical screws to fix broken bones together.

’There is a lot of interest in nanodiamonds for composites because they are not only very hard but have interesting surface chemistry,’ says Milos Nesladek, who researches nanodiamonds at Hasselt University in Belgium. He suggests the work could be combined with other research into loading drugs onto the surface of nanodiamonds to make medical implants that release drugs to aid healing or reduce inflammation as they degrade.

References

et alBiomater.32, 87 (DOI: 10.1016/j.biomaterials.2010.08.090)

No comments yet