Adding tiny cone structures and a coating of graphene oxide can make a variety of surfaces frost-resistant for over 150 hours – 1000 times longer than current methods. The technique is also scratch and crack-resistant and could be used to help maintain infrastructure in cold and humid climates.

Frost formation can be annoying in everyday contexts, but costly and dangerous when it affects infrastructure like outdoor power cables and heat exchangers. Traditional anti-frosting methods, such as superhydrophobic coatings or lubricant-infused surfaces, work only for a relatively short time and are limited by their vulnerability to scratches and environmental contaminants.

The novel approach combines adding millimetre-scale cones that can be made from a range of different materials to a surface with a 600nm thick coating of hygroscopic graphene oxide between peaks. The cones help to concentrate water vapour at the peaks, allowing frost to form sacrificially while the flat valley areas between remain frost-free. The graphene oxide coating further suppresses frost formation by adsorbing water vapour and maintaining undersaturated conditions.

When tested under high humidity at -12°C, the valleys of the macrotextured graphene oxide-coated surface resisted frost formation completely for 160 hours, compared with a lubricant-infused surface and a superhydrophobic surface that resisted between 5 and 36% of frost formation.

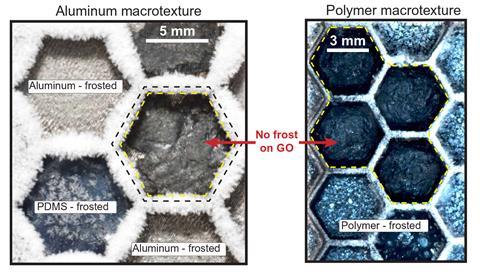

The researchers demonstrated that their technique could be extended over large areas by making hexagonal patterns of graphene oxide-coated cells out of aluminium, polydimethylsiloxane and plastic. They also showed that the graphene oxide coating is effective at frost prevention even when scratched or contaminated with plastic particles.

The team theorise that the frost prevention potential of this robust material could be further enhanced by adding a de-icing mechanism, such as a low interfacial toughness surface, to the macrotexture peaks to help eliminate any accumulated sacrificial frost.

References

C Machado et al, Sci. Adv., 2024, 10, eadq8525 (DOI: 10.1126/sciadv.adq8525)

No comments yet