Device beats previous efficiency record of 15.6%, reaching nearly 20%

Scientists in Switzerland, who last year made the first perovskite solar cell with an accredited efficiency, have now trumped their own record. Recognised by one of the only solar cell test laboratories in the US, their new cell has a certified efficiency of 19.6%.

The rise of perovskite solar cells has been anything but slow. Within the past six years, efficiencies have risen by over 18% and some believe perovskite devices may eventually put silicon-based technologies in the shade.

But officially recognised efficiency values have been thin on the ground. To achieve accreditation, a 1cm2 solar cell must remain stable for 1000 hours when exposed to 1000Wm-2 of sunlight. Based on these criteria, national test centres have been unable to verify virtually any efficiency measurements for perovskites, with some cells degrading spontaneously in air or simply being too small to test.

Part of the problem may stem from the way some perovskite devices are manufactured, according to Michael Grätzel from the Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland. ‘The perovskite community uses this anti-solvent method,’ he says. This involves spin-coating a perovskite solution, often containing the solvents gamma-butyrolactone (GBL), dimethylfomamide (DMF) and dimethylsulfoxide (DMSO), onto a titanium dioxide substrate. As the solution is spinning, chlorobenzene is added to the centre, which spreads across the surface and stimulates perovskite film growth.

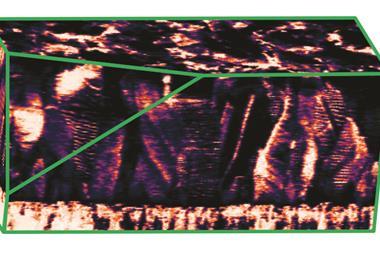

The resulting films are often uneven and full of impurities. ‘You spin the drop and it has more in the middle than at the border of the film – the anti-solvent is problematic,’ says Grätzel. ‘Chlorobenzene is [also] toxic and an unwanted chemical.’

Grätzel’s group has taken a different approach. ‘It’s embarrassingly simple,’ he says. ‘The shortcut we have found is to apply this mild [vacuum], just for a few seconds, and that does away with the anti-solvent.’

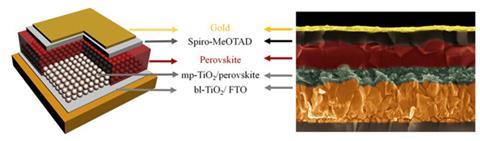

Rather than apply an anti-solvent to precipitate out the perovskite film, the team applied a vacuum for 20 seconds. This vacuum-flash solution processing (VASP) treatment removes the GBL and DMF solvents, leaving behind a smooth DMSO–perovskite film that completely covers the substrate. The film is then heated to 100°C to remove the DMSO.

‘It offers a method to get to high quality electronic grade perovskite at low temperature – you never go above 100°C – and a very mild vacuum,’ says Grätzel. The vacuum is so mild it could be created with a water jet pump.

Such a small change in the manufacturing process has a large impact on the perovskite’s stability and efficiency when incorporated into a solar cell structure. The team recorded a maximum electric power conversion efficiency of 20.5% for a 1cm2 cell. This value was revised down to 19.6% when tested by Newport, an accredited test laboratory based in the US. The EPFL group also found the cell remains stable in air for up to 39 days.

For Eva Unger, a postdoctoral researcher at Lund University, Sweden, whose research has been geared towards highlighting the perovskite stability problem, VASP is attractive due to its scalability. ‘The results achieved in terms of efficiency are comparable to results achieved using the “solvent-drip” approach, but VASP is likely more feasible to implement in larger area processing,’ she says.

References

X Li et al, Science, 2016, DOI: 10.1126/science.aaf8060

No comments yet