Growing cells on flat, plastic culture plates or petri dishes is a poor substitute for the three-dimensional support matrix that would naturally surround those cells in a living organism. UK start-up Biogelx, based at BioCity Scotland in Newhouse, is developing self-assembled peptide hydrogels that can provide support to growing cells, but also present well-defined surface chemistry to help cell biologists address biological problems.

‘There are other 3D scaffolds and matrices out there,’ says Eleanore Irvine, the company’s product development manager. ‘But often they are made from animal derived products or use very complex peptides – so they only offer one type of gel that’s meant to be used with any cell type. We can tune our gels to offer different stiffnesses, so if you wanted to grow brain cells we would give you a soft gel, but if you wanted to grow bone cells we’d move to a more rigid gel.’

‘There are other 3D scaffolds and matrices out there,’ says Eleanore Irvine, the company’s product development manager. ‘But often they are made from animal derived products or use very complex peptides – so they only offer one type of gel that’s meant to be used with any cell type. We can tune our gels to offer different stiffnesses, so if you wanted to grow brain cells we would give you a soft gel, but if you wanted to grow bone cells we’d move to a more rigid gel.’

Into the matrix

The problem with these complex or animal-derived products is control · the stiffness and surface chemistry of the gel affect how well different cells grow. Having simple and chemically well-defined building blocks allows researchers to probe these interactions systematically, and tune the conditions to achieve the desired result.

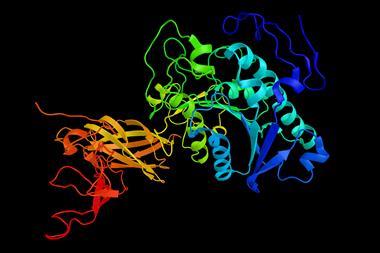

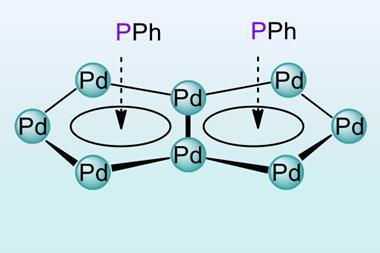

‘There are two components, which essentially have assembly instructions built into them,’ says Rein Ulijn, whose group at the University of Strathclyde provided the basis for spinning out Biogelx. ‘One is structural – it has instructions to form unidirectional fibres. The other is functional – it will associate with the fibres and present the desired chemistry on the surface.’

The gel components are dipeptides, functionalised with end-groups that help them self-assemble. The gelation reaction is triggered by divalent cations, such as calcium, which crosslink the gel fibres to set the gel. ‘By playing around with the cross-linking density, we get control over the stiffness,’ Ulijn explains.

It is no coincidence that calcium salts are present in most common cell culture media. When the precursor solution comes into contact with the culture medium, the gelation process is triggered instantly, Ulijn says. Within 45 minutes the gel is stable and ready for use in cell culture.

Keeping it simple

Because the building blocks are very simple, and rely on supramolecular interactions to build complexity, it becomes possible to tweak and tune the gel properties. Rather than making the peptide components bigger and more complicated, Biogelx can put together more complex mixtures, while keeping the individual molecular components small and simple – and hence easier to synthesise on scale.

‘Because our approach is based on dipeptides, systematically changing one amino acid has pronounced effects, which may be predicted,’ Ulijn says. Using small peptides also puts computer modelling of the self-assembly within reach, which opens the door to more rational design approaches. ‘We’re trying to build up a set of design rules for creating functional structures with these building blocks,’ he adds.

‘Our approach is inspired by biology · because biology produces fantastic functional nanostructures,’ says Ulijn. ‘We’re trying to do some of the things that biology can do so wonderfully well, but with systems that we can access as chemists. It’s a reductionist approach – how simple can it be but maintain that functionality?’

Support for growth

At the moment, Biogelx is predominantly operating in the 3D cell culture market. ‘We’re selling products to academics and [small and medium-sized enterprises] through collaborative contracts,’ says Irvine. However, the company has its sights set on much bigger markets such as incorporating its products into screening assay kits, or growing artificial tissues for implant in regenerative medicine.

But Ulijn is clear about where Biogelx’s strength lies: ‘We are unapologetically materials chemists – we’re not biologists and we’re not trying to address biological problems on our own.’ That, he says is best left to the company’s network of customers and collaborators.

Realistically, Irvine says, the best way into those larger-scale applications is going to be to develop the right products and then license them to a bigger pharmaceutical or biotechnology firm. As one of the 2013 winners of the Royal Society of Chemistry’s Emerging Technologies competition, Biogelx has been working with mentors at GlaxoSmithKline. Irvine explains how this has informed the company’s strategy. ‘We’ve now got a much earlier sense of how we need to change and develop the product, so we can shape the business around that,’ she says. ‘The insight from that has been invaluable.’

No comments yet