Controlled curling – a new way to go from flat to 3D

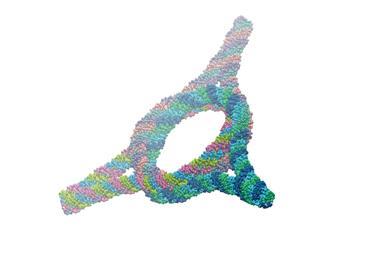

Researchers in the US have developed a new way to curl polymer sheets to create a variety of 3D structures.

Shape memory polymers change shape in response to external stimuli such as light and heat. Chemists add active materials to polymer sheets, which then deform on stimulation. Usually the active materials are placed in regions where curvature is desired, but Michael Dickey, Jan Genzer and their colleagues at North Carolina State University have now shown they can deform regions adjacent to the active materials.

They used an inkjet printer to pattern polystyrene sheets with ink. Patterned regions absorb more infrared light than unpatterned regions. On heating, ink-covered areas shrink, creating internal stresses in adjacent, non-inked regions. By varying ink patterns on the polystyrene sheet, the team turned them into a variety of 3D shapes.

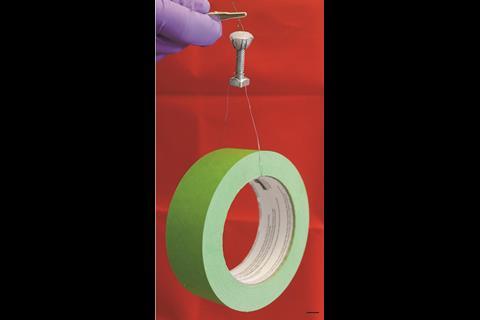

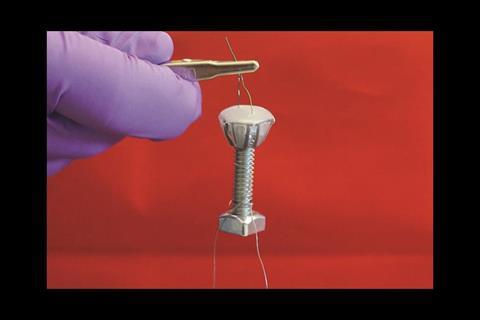

The team used computational modelling to predict how they might generate different shapes, and the results helped them design a functional gripper that could hold about 925 times its own mass.

References

This article is free to access until 14 April 2017

A M Hubbard et al, Soft Matter, 2017, DOI: 10.1039/c7sm00088j

No comments yet