Solar jet fuel production from CO2 and water scaled up in field demo

Concentrated solar power provide heat to reduce carbon dioxide to a fuel

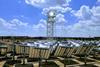

In a world first, kerosene has been synthesised using solar energy, water and carbon dioxide in a fully integrated solar tower setup. An array of 169 spherical reflectors concentrated solar radiation onto a reactor mounted on a tower near Madrid, Spain providing the thermal energy for the conversion.

The reflectors delivers around 50kW of solar radiative power – equivalent to 2500 suns – directly into the 16cm wide aperture of the reactor. ‘There are reflecting mirrors which track the sun and redirect and concentrate the solar radiation to the top of the tower,’ says lead researcher Aldo Steinfeld at ETH Zurich, the Swiss Federal Institute of Technology.