Acoustic technique that measures physical changes could simplify battery tests

Researchers in the US have shown that ultrasound echoes can indicate density changes to provide a simple and non-invasive method for measuring charge within any battery.

Batteries are typically made up of metal layers but these layers, and their chemistries, vary with battery type. Each exhibits unique cycling and charging behaviour, so different batteries are assessed in different ways. Expensive equipment, like synchrotron light sources, can provide fine physical insights into a battery’s state. But these techniques aren’t easily accessible to all researchers.

Ever growing research into energy storage means there is a need for a cheap and universal method to measure battery health, so that scientists have a convenient way of scrutinising their research. So following on from their previous work, where a bounce test was used to denote battery health, Daniel Steingart and coworkers at Princeton University were inspired to design a straightforward solution.

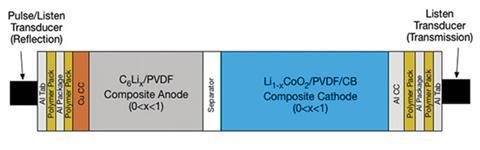

By pulsing ultrasound waves at batteries, they correlated echoes as the batteries charged and discharged to mass movement within the cell’s layers. ‘It’s like you’re tapping it to see how loud the battery is as a drum. Depending on its state of charge, it will be a louder drum in certain places than others and that gives us real insight into what’s happening within the cell,’ Steingart says. Performing these experiments on several alkaline and lithium battery cells, including commercial Duracell and CVS AA batteries and the lithium-ion cell thought to be in Tesla Motors’ model S electric car, they saw that at charge and discharge the echoes were showing obvious differences; monitoring these changes allowed them to determine key information on the physical processes happening within the different batteries.

‘What excites us about this is that the technique taps into something that is fundamental to all batteries,’ explains Steingart. The intricate structure of layers within an individual cell and the density within those layers can be used to produce a fingerprint to verify the state of the battery and its charge at that time. He explains that the geometry of a battery and its construction are as important as the chemistry inside.

Brian Sheldon, an expert in materials science and engineering at Brown University in the US, is impressed with this new technique: ‘There are significant challenges associated with obtaining information about internal changes in these structures, and this method offers a novel approach. Because ultrasonic technology is used for in situ imaging in other fields, I think there is significant potential to develop important new tools that can be used commercially.’

References

This article is free to access until 2 June 2015. Download it here:

A G Hsieh et al, Energy Environ. Sci., 2015, DOI: 10.1039/c5ee00111k

No comments yet