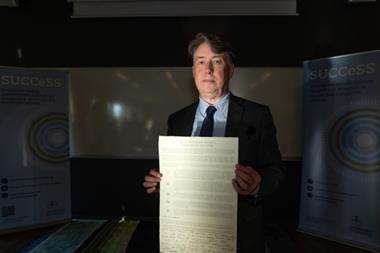

Twenty-five years ago, John Warner and Paul Anastas challenged the chemistry community. Their influential book, Green Chemistry: Theory and Practice contained the 12 principles of green chemistry and as Anastas says, ‘the whole purpose was to say, in a phrase, we can do better’. The last century of chemistry brought about advances to quality of life, innovations, and inventions, but not without costs to the environment and human health. For Anastas doing better meant keeping the good without all the harm.

Twenty-five years on from the publication of this green chemistry manual he believes green chemistry has been more successful than anyone thought possible. ‘In the 90s, there was a legitimate question, can we do this?’ Anastas recalls. ‘I would say that on this anniversary, the question has been asked and answered, and the answer is yes, we can.’

25 years is about how much time you would need to expect to see a significant difference

John Bissell, chief executive of Origin Materials

Today entire journals dedicated to green and sustainable chemistry are full of new materials, synthetic methods and discoveries. Start-ups are pioneering these innovations from sustainable jet fuel, biodegradable plastics and chemicals produced using plant-based feedstocks. Yet while there is wide recognition that operating according to green chemistry principles is the way forward, and that it is economically feasible, there is still more to do. According to Anastas the question now is not can we, but will we? ‘Will we have the will to invest, the will to change, the will to transform at complete scale?’ he asks.

Making a start

From renewable energy to electric cars, new technologies have always had to fight to replace the incumbent technology, even when they are clearly improvements. John Bissell, chief executive of Origin Materials, which won an EPA Green Chemistry Award in 2022, says this is part of a normal cycle. ‘It just takes a long time to invest enough capital to cycle all the way through a technology,’ says Bissell. He points to Solvay needing several decades until its cheaper, cleaner and more efficient process to produce sodium bicarbonate replaced burning Europe’s forests to get potash. When it comes to green chemistry, Bissell believes more progress has been made than most realise but we are still at the beginning of this change. ‘I would argue that 25 years is about how much time you would need to expect to see a significant difference,’ Bissell says, ‘not all the difference, not getting all the way but a difference.’

Anastas agrees that while green chemistry is widely viewed as the future, it is not yet the industry standard. The recent train derailment and spill of toxic vinyl chloride in East Palestine, Ohio, in the US is a stark reminder that the chemical industry has not fully embraced green chemistry. ‘Do we know higher performing materials that can be based on safer monomers, of course we do,’ says Anastas, ‘but it is overcoming those shutdown economics, those entrenched processes and supply chains that is simply the biggest impediment.’

For Anastas the success of green chemistry goes beyond individual breakthroughs that make specific processes a little bit cleaner, or slightly less wasteful. Chemistry touches all aspects of the economy and of our lives, he notes. ‘If you shift the conceptual construct around how we do chemistry, that’s also going to touch all aspects of our lives,’ he adds. Now he believes people are beginning to realise what a fundamental shift this is and that each new catalyst, solvent or synthetic methodology doesn’t exist in a vacuum. ‘Our ability to design in terms of systems design, and systems chemistry gives us way more impact than we ever imagined,’ he said.

Changing our ways

Francesca Kerton , a chemist at Memorial University of Newfoundland, Canada, has seen this impact firsthand. In working with local seafood producers to find ways of processing waste, such as chitin and calcium carbonate, to obtain renewable chemical feedstocks for other industries her lab trialled commercially available enzymes used as laundry detergents. Kerton explored using these enzymes at different temperatures and without the buffers recommended by the supplier. ‘Although it might work better at say 45°C or 55°C, the reactions work well enough if you run them at room temperature,’ she says. This commitment to green chemistry led to a sustainable solution with commercial potential. It also has the broader impact of keeping costs low and methodologies simple, something Kerton believes makes chemistry more accessible to everyone.

In the next 25 years Anastas urges chemists to remember the original challenge: doing better. ‘When I hear people talk about sustainable chemistry, one of the things that concerns me is that too many folks are using this in ways of, here’s what you can’t do, here’s what you have to eliminate, ban and minimise,’ Anastas says. He sees green chemistry designing a sustainable future through innovation not scientific handcuffs. ‘The evolution of green chemistry has been about building community around wanting to pursue this, but recognising the whole time that this is continuous improvement,’ he says. ‘We’re holding up this goal of perfection called green chemistry, but everybody knows that there’s no such thing as green chemistry, there’s only greener chemistry.’

No comments yet