Filling a vacuum in the low-pressure lubricant market

Do you believe in ghosts? No doubt you scoff at the suggestion. But as I grow older, I sometimes wonder… Let me explain. I am standing in the lab in front of the twin manifolds with which I will re-enact the pump-fill protocol that Wilhelm Schlenk developed in the 1920s. After flicking on the pump, giving thanks to Wolfgang Gaede, I raise James Dewar’s flask around the trap and pour in a litre or so of liquid nitrogen, mentally tipping my hat at William Hampson and Karl Linde. With my left hand I reach up, familiarly opening James Young’s Teflon valve. With my right hand I flick on the Pirani vacuum gauge – the needle swings. The vacuum is good, but not great. Leaning in slightly I work the double-oblique stopcocks back and forth, paying homage to Clemens Winkler and Fritz Friederichs.

To my immense irritation, however, the vacuum isn’t great and working one tap it gets a bit worse. I peer grumpily at the stopcock; sure enough a line of streaks mars the clarity of the barrel. It’s time to clean and regrease the tap.

I am using the ubiquitous Dow Corning silicone grease. It’s easy to use and familiar, but glassblowers loathe it because when heated in the annealing oven it burns, leaving a thin cloudy residue that makes glass impossible to join. As I wipe the tap and apply two thin lines of translucent goo to the key, I wonder what people did before Hy-vac grease became available.

Stopcocks really came into their own in the 19th century as vacuum came to occupy a central place in the physical sciences. The development of mercury pumps by the likes of Heinrich Geissler, Hermann Sprengel and August Töpler caused a whole new world to emerge, where physics and chemistry were a seamless whole. Glass stopcocks became central to the control of this low pressure world, each individually ground with emery to ensure a close fit. The stopcock would then be lubricated and sealed using tallow or similar fat.

But such grease failed several of the tests that R T Sanderson would document in the 1940s. It tended to flow out of the tap during use, and would stiffen and seize when left unused. In addition to having a significant vapour pressure, it tended to absorb solvents and change in viscosity. It also stiffened or melted as temperatures fell and rose. Something more reliable was needed. The replacement appears to have been developed in the laboratory of William Ramsay, the Scottish chemist who brought together the latest techniques in physical science to find the noble gases.

Noble pursuit

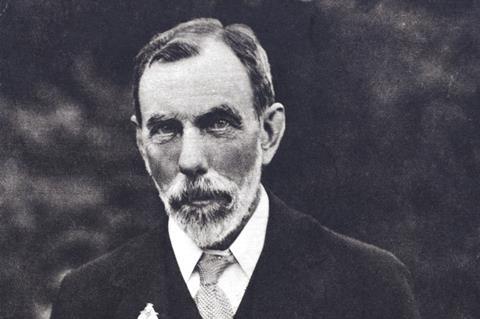

Ramsay first studied at the University of Glasgow, afterwards heading to Heidelberg, Germany, where he might have become a spectroscopist with Robert Bunsen. But his parents’ fears of the Franco–Prussian war forced him to return to Glasgow. When things had settled, he went to Wilhelm Fittig’s labs in at the University of Tübingen instead to do organic chemistry. Ramsay’s doctoral thesis was only 27 pages long. In 1872 he returned to Glasgow, and in 1879 became principal at Bristol where his work explored thermodynamics, measuring vapour pressures and gas solubilities, and establishing critical parameters.

In 1887, Ramsay was appointed professor of chemistry at University College, London (as it was then punctuated). Around this time William Strutt, Lord Rayleigh, noticed that nitrogen made by removing oxygen, moisture and carbon dioxide from air was 0.1% denser than nitrogen made chemically. Ramsay, with all his experience, was in a perfect place to attack the problem.

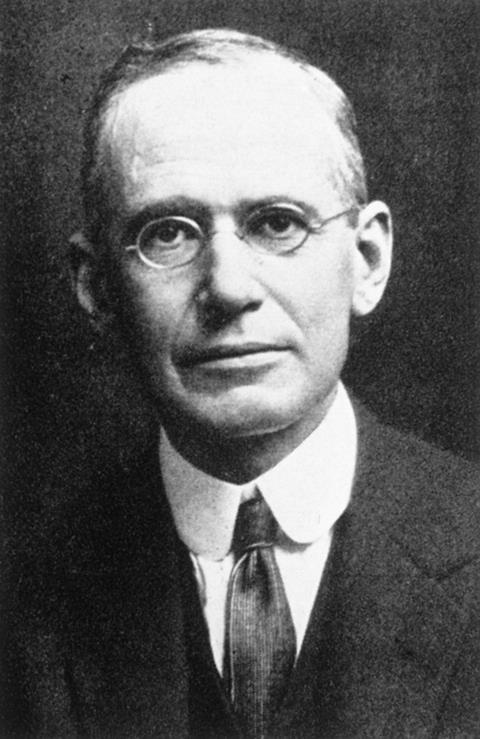

Ramsay began scrubbing tens of litres of air of their components, eventually isolating pure samples of what he and Rayleigh named argon (from the Greek, the idler) because of its apparent lack of reactivity. Next Ramsay, with the help of a key assistant, Morris Travers, was able to isolate helium, and then, using increasingly sophisticated pumping and manipulation routines involving liquid air, discovered neon, krypton and xenon.

None of this would have been possible without a really reliable lubricant for stopcocks. In his 1901 monograph The Study of Gases, Travers describes ‘a very efficient lubricant’ made by melting ‘two parts soft rubber clippings, one part Vaseline and one-eighth part hard paraffin wax heated together in a basin in a sandbath’. The black, sticky viscous goop made the isolation of the noble gases possible. It began to be marketed as ‘Ramsay Fett’ by the pump manufacturer Leybold Nachfolgers from around 1910; it had a vapour pressure of less than 10–6mmHg (as measured using a Knudsen gauge in 1914). Frederick Lindemann, annoyed by the cost of the grease when head of the Clarendon Lab in Oxford, would donate his old golf balls to his colleagues so they could make vacuum grease with the rubber from the core.

Astonishingly, in spite of the availability of various hydrocarbon, silicone and perfluorinated alternatives today, you can still buy Ramsay grease in Germany. But for me, turning the taps on my vac line, I’ve realised that there are two more ghosts – Ramsay and Travers – standing beside me as I work.

References

M Travers, The Study of Gases, McMillan, London, 1901

R T Sanderson, Vacuum manipulation of Volatile compounds, Wiley, 1948

No comments yet