Flasks with built-in nanoparticles allows chemists to easily reuse valuable catalysts

Lab glassware with built-in palladium nanoparticles makes recycling and reusing valuable metal catalysts easier than ever before.

Metals like platinum or gold can catalyse a plethora of chemical reactions, but they are expensive, which is why chemists reuse and recycle them. Usually, the solid catalyst needs to be separated by filtration and purified after a reaction, which can mean some is lost and recovery can be particularly difficult if any of the reaction products is solid too.

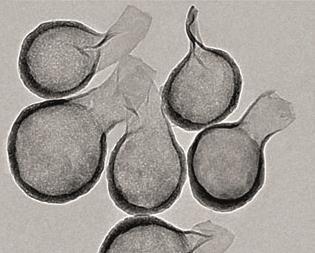

Now Xiang Fei from the National University of Singapore and colleagues have coated flasks with palladium nanoparticles, which means chemists can simply empty and rinse the reaction vessel and then use them to catalyse the next reaction.

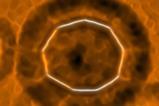

As metal nanoparticles don’t stick to glass, Fei’s team covered the glass with a microscale carpet made of silicone nanofilaments and they coated them with a sticky protein similar to the one mussels use to attach themselves to surfaces. The coated flask still catalysed reactions efficiently after being used 20 times, whereas a commercial catalyst’s efficiency drops significantly after it has been recycled only once.

Fei’s team saw no decrease in the catalytic flask’s efficiency when used to produce several grams of product, but it isn’t clear yet if the method would work in industrial-sized reactors.

References

X Fei et al, ACS Catal., 2017, 7, 2412 (DOI: 10.1021/acscatal.6b03185)

No comments yet