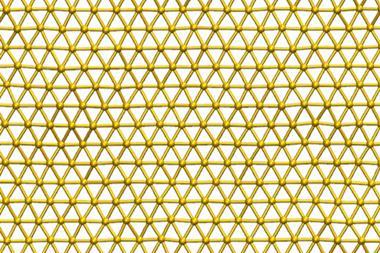

A new one-pot mechanochemistry method for processing elemental gold can provide organosoluble gold salts in under one hour. By combining potassium peroxymonosulfate, a common pool cleaner, tetraalkylammonium halide salts and metallic gold in a solvent-free ball mill reaction, the technique avoids traditional harsh and toxic reagents used for gold oxidation.

As a noble metal, gold is incredibly resistant to most chemical processes. This quality makes it valuable for a wide range of commercial and technological applications but also necessitates using chemically aggressive reagents to process it. Current methods for gold refining use reagents including aqua regia (a mixture of concentrated hydrochloric or hydrobromic acid with nitric acid), chlorine gas and mercury, which pose a concern for the environment and workers. ‘The way gold is processed is really messed up,’ comments Tomislav Friščić, at the University of Birmingham, UK. ‘It’s horrible, it’s filthy, it’s bad and it’s dangerous as hell.’

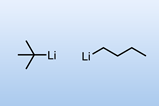

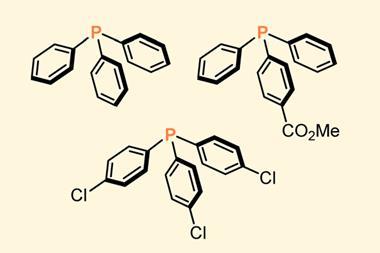

Spurred on by difficulties acquiring commercially available gold salts, Friščić’s team sought a safer alternative to traditional gold salt synthesis methods. They added bulk gold, tetraalkylammonium halide salts and potassium peroxymonosulfate to a ball mill. After 30–60 minutes of milling, an organosoluble tetrahaloaurate (iii) salt results that can be separated from sulfate byproducts in high yield after a single extraction with ethyl acetate.

By minimising the solvent used during synthesis and the number of extractions and post-processing steps that must be performed, the environmental footprint of processing metallic gold into usable salts is significantly reduced. The ethyl acetate used for extraction can be reused multiple times.

Traditional gold manufacturing technologies do not allow for the use of these reagents. ‘In industry, the temperatures at which they do these processing steps are way too high. You would just burn off the salt, but by using mechanochemistry, you can use these unconventional reagents,’ explains Jean-Louis Do, a PhD student in Friščić’s group who previously worked in a lab processing a rare palladium gold ore via boiling sulfuric acid immersion.

The team further investigated mechanochemical processing of gold by milling freshly prepared tetrahaloaureate (iii) salts with anhydrous sodium acetylacetonate for 30 minutes, reducing the compounds to air and moisture stable dihaloaureate (i) compounds. ‘For us, it was really exciting because within two hours we went from gold powders to a salt that people want to use’, explains Thomas Auvray, a senior research fellow in Friščić’s lab.

![3D visual representation of TBA[AuCl4]](https://d2cbg94ubxgsnp.cloudfront.net/Pictures/web/u/c/p/visualrepresentationoftbaaucl4_666627.gif)

‘The most striking point to me is that it oxidised that which is believed to be unoxidisable,’ says Erli Lu, a rare-earth metal chemist from the University of Newcastle, UK. ‘The oxidation step is actually the bottleneck of all gold coordination chemistry… If you have the gold +3 complex, you can do whatever you want.’

Lu would like to see this methodology applied to selectively oxidise gold over other metals like silver that are commonly found in complexes in natural ores. Friščić and his team agree. One of their next areas of investigation will be ‘selectively oxidising certain metals over others, by tuning the reaction conditions,’ says Do. Friščić adds, ‘if you want to be very enthusiastic, imagine you can have a mechanical process that you can tune to selectively activate five, six or seven noble metals.’

Friščić is hopeful that this safer and greener method of processing gold could find widespread use in industry without requiring massive reforms to existing infrastructure: ‘You make exactly the same stuff, but now you make it in a much safer way. You don’t need to dismantle the whole of industry; you can just replace a nasty, horrible step with essentially a pool cleaning agent-based one.’

1 Reader's comment