Safer fluorination process developed using flow electrochemistry

Automated system for constructing carbon–fluorine bonds quenches fluorine compounds to reduce exposure and risk to lab chemists

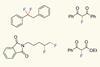

UK-based researchers have combined fluorine chemistry, electrochemistry and flow chemistry to develop a fully automated flow system for fluorination reactions. By quenching hazardous fluorine-containing reagents in situ, the system should decrease exposure risks for experimental chemists.