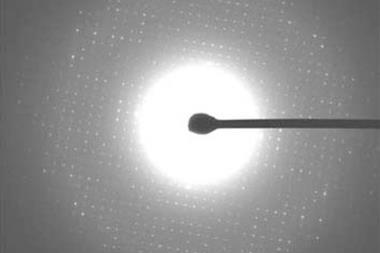

The first national centre dedicated to electron diffraction will open in the UK this summer. The new centre will give the country’s research community access to a technique that can determine the molecular structures of much smaller crystals than other methods. The team behind the centre suggests it will become a game changer for the chemical industry, including manufacturing, pharmaceuticals and electronics.

Funded by a £3.2 million grant from the Engineering and Physical Sciences Research Council (EPSRC), the National Electron Diffraction Facility will be based jointly at the University of Southampton and the University of Warwick. It will be part of the National Crystallography Service (NCS), a key component of the UK’s research infrastructure that has underpinned many scientific discoveries and developments.

‘Historically, the NCS has really pushed the boundaries of what is possible by x-ray crystallography,’ says Simon Coles, a structural chemist and project lead for the University of Southampton site. ‘This new facility provides a step-change in structure analysis, not just to samples that only grow tiny crystals, but also to whole sub-disciplines such as solid state chemistry, MOFs etc where before only very limited characterisation was possible.’

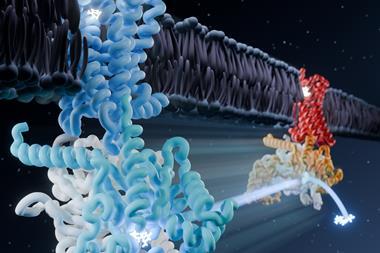

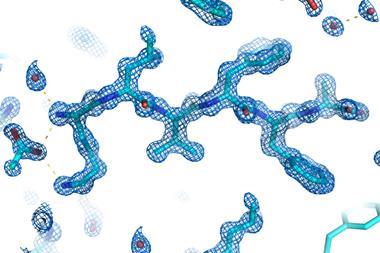

Electron diffraction characterises crystal structures much like x-ray diffraction – the gold standard for structure determination – except it uses an electron beam instead of x-rays. When an electron beam is fired at a sample, the crystal lattice of the material scatters the electrons to produce a diffraction pattern, which reveals the structural orientation of atoms in the sample.

‘It’s really pleasing to see the EPSRC investing further in the National Crystallography Service,’ comments Derek Wann, an electron diffraction expert at the University of York. ‘The complementary use of electron diffraction will allow the tiniest of crystals to be studied and this is particularly exciting in our quest to understand novel materials.’

The new facility will feature two of the world’s first dedicated XtaLAB Synergy-ED diffractometers produced by instrument manufacturer Rigaku. These will be housed in refurbished laboratories in Southampton and Warwick, which will also include sample preparation facilities and space for visiting researchers to work and integrate with the NCS team. As the user interface and software of the new diffractometers is exactly the same as the x-ray diffraction systems currently used at the NCS, the transition to electron diffraction should be simple.

‘This exciting new instrument will enable us to study many crystalline materials that previously were difficult or impossible to grow into suitably sized crystals to be measured by x-ray diffraction techniques,’ says David Walker, project lead at the University of Warwick. ‘This will revolutionise our understanding of the structure of many economically important materials including pharmaceuticals, catalysts, batteries and energy storage materials leading to breakthroughs in these areas.’

Wann thinks the facility could open up other opportunities too. ‘Electron beams can be very versatile, and one additional benefit could be around further development and commercialisation of interesting electron sources,’ he says. ’There are overlaps that are still to be exploited between those working in electron crystallography, gas electron diffraction and various forms of electron microscopy – including cryo-EM.’

The National Electron Diffraction Facility will open to academic and commercial partners in July 2023.

No comments yet