It is difficult to imagine a world without plastics. From the clothes we wear, the items in our houses and the components in our cars to the way so many of the things we buy are packaged, plastics are everywhere. But it is increasingly clear that, useful as plastics are, plastic waste is a massive, and increasing, problem.

Take plastic packaging. By its very nature, it is likely to be thrown away once the product has been opened and used. But, as the predominant application for thermoplastic resins, the plastic packaging waste mountain is growing relentlessly. And as a major product of the petrochemical industry, it is unsustainable at the start of its life, as well as at the end of it.

Every part of the plastics value chain needs to adapt

Els Verdonck, senior applications scientist, TA Instruments

Yet plastic is the obvious choice for packaging so many products. It’s lightweight and durable, it provides safe and hygienic containment for food, medicines, and personal care products, even reducing food spoilage and, of course, it is cost-effective. But, despite efforts locally and nationally around the world, recycling rates remain low.

If we are to continue using plastics, then these recycling rates will certainly have to rise. Recycled resin is already finding its way back into every part of the supply chain, from raw materials suppliers through polymer manufacturers, masterbatchers and converters, right through to reuse in end products. ‘This requires the plastics industry to innovate, and develop new products,’ says Els Verdonck, senior applications scientist at the TA Instruments division of Waters Corporation. ‘Every part of the plastics value chain needs to adapt.’ And finding ways to make new virgin plastics from non-fossil fuel-based raw materials will also be essential in the drive towards a more sustainable future.

Mechanical recycling

The vast majority of plastic recycling is currently mechanical – essentially, reusing the polymer in some way. This can be effective in reducing energy use and global warming impact compared to using virgin raw materials. But it also poses new challenges for plastics makers and users.

The variability and contamination in the plastic waste stream is, inevitably, a complicating factor for mechanical recycling, and identifying exactly what is in the waste is going to be crucial to success. ‘All of a sudden the industry is moving from processing homogeneous virgin plastics to incorporating recycled content that can vary a lot from batch to batch,’ Verdonck says. ‘Therefore proper fingerprinting and process optimisation becomes increasingly important.’

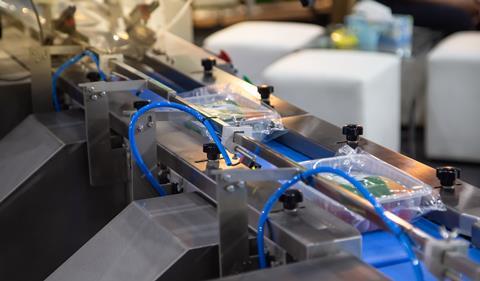

Waste plastic is delivered in bales to the mechanical recycling facility, where it is first sorted and inspected by eye or with the assistance of infrared (IR) spectrometry, and then washed before being chopped into small pieces. These flakes are fed into a sink–float tank, where their relative densities mean polyolefins float while polyethylene terephthalate (PET) sinks. This helps to separate and decontaminate the waste stream, although it is not infallible: a polyethylene bottle might have a polypropylene cap, and both would float. Therefore, another IR scanner might be used here, too, which might get the material up to about 98% pure.

However, both these separation techniques tend to fail for multilayer films, which might contain outer layers of polyethylene for food contact, with further layers of polyamide to confer strength, and other materials to give protection from oxygen. As these are all stuck together, separating them is not simple.

After sorting and drying, the polymer shards are melted and pelletised. These pellets can then be used to make new products.

The energy savings over using virgin resin are significant. Life cycle analysis from the US Association of Plastic Recyclers suggests that recycled PET, for example, cuts energy usage by about 80%. And the emissions of greenhouse gases can be reduced by as much as three-quarters, too.

Checking for impurities

Despite the care taken to ensure the material that is mechanically recycled is as pure as possible, analysing the reprocessed material is important, and the results of this analysis can help guide reprocessing conditions. Both thermal analysis and rheology assessments have a great deal of value here.

Two techniques predominate for thermal analysis: differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA). Both give an insight into how variable waste plastic is, which helps to decide how it might be processed more efficiently.

[Our] thermal and rheological instruments provide the most comprehensive analysis to polymer industries

Terri Chen, principal applications engineer, TA Instruments

DSC measures how much heat is absorbed or released by a material sample during heating or cooling. This gives information about the material’s glass transition, the temperature ranges of melting and crystallisation, and even its oxidative stability. Only small samples are required – of the order of a few mg – and powders, granules, films and liquids can all be tested.

The technique can also be used to qualify and quantify organic contamination in recycled polymers, which gives vital insight into how the polymer should be processed. Different polymers have distinct, known glass transitions and melting temperatures, so any unexpected peaks will indicate the presence of contaminants.

DSC can also assist in determining the best processing temperature for the resin as it allows the melting temperature range to be determined. The endset of the melting region will be the minimum temperature for processing because, clearly, the resin must be molten in order to be processed.

At the other end of the processing window, TGA can be used to determine the maximum processing temperature. TGA measures how a material’s weight changes as a function of temperature or time, which can be used to indicate the point at which a material begins to decompose, as well as quantifying the volatiles present, and it can even give some sense of the filler content within the resin.

Rheology – the science of flow and deformation of matter – can give further details about the polymer architecture, such as molecular weight, molecular weight distribution and long chain branching structure. ‘It provides a direct measurement of a polymer’s melt flow behaviour, showing how stable the resin is at the processing conditions. A rheological analysis can also help to guide and optimise the processing temperature through measuring the melt viscosity change as a function of temperature,’ says Terri Chen, principal applications engineer at TA Instruments.

Advanced recycling and alternative inputs

While mechanical recycling is very sensitive to contamination in the waste stream, advanced recycling can cope with less homogeneous plastic waste and can give much purer feedstock . This is achieved by chemically recycling the polymer in some way, rather than simply reprocessing it. The downsides are that these techniques are less well developed than commercial technologies and can be a lot more energy intensive.

Depolymerisation is furthest advanced for polyesters (like PET) and polyamides. This takes the polymers back to their base monomers, which are then repolymerised to make new resin. Conversion takes the concept a step further, breaking the plastic down by gasification or pyrolysis into petrochemicals or even syngas, returning it right to the start of the petrochemical chain. This is predominantly applied to polyolefins.

The other way in which the environmental impact of the plastics chain might be reduced is to use non-petrochemical sources as raw materials for the monomers and polymers. There has been a lot of interest in the potential of using bio-based raw materials instead of oil. This is still in its infancy, but reasonable strides have been made in the polyurethane sector, where bio-based polyols are already being used by shoe manufacturers, for example. Capturing waste carbon dioxide streams might also be an option, such as the EU Carbon4PUR project to convert off-gases from ArcelorMittal’s Marseille steelworks into monomers.

Even with mechanical recycling, further work is required on better ways to sort waste into polymer types to facilitate recycling – and not all types of plastics can yet be recycled easily, if at all. ‘How do you ensure the recycled plastic you receive is 100% pure – or at least has a higher level of purity?’ says Michael Onepe, market development manager at TA Instruments. ‘And how can we design plastics so they can be recycled more easily?’

Indeed, careful design of materials and products could greatly assist in ramping up recycling rates. Food packaging films, for example, might be made using fewer layers, if this could be achieved without impacting performance, and those layers might be made simpler to separate. Block copolymers might be added to immiscible recycled mixed polymers to enhance compatibility of the resulting plastic. Additives can also play an important role in recovering useful polymer resin. Antioxidant and antacid additives are generally included in virgin polymer systems, but adding more to replenish those that are destroyed or degraded during processing can reduce damage to the polymer chains during reprocessing.

Scott Trenor, principal scientist at Milliken, cites the example of how the company’s DeltaMax® performance modifiers for polypropylene were able to help compatibilise plastic waste for a customer trying to incorporate recycled PP into an injection moulded garden seat. ‘They were having problems processing materials because of contamination, mostly polyethylene, in the recycling stream,’ he says. ‘By using 1wt% of the additive, they were able to increase the amount of recycled material from 40% to 90%.’ Further sustainability enhancements included a 20°C reduction in processing temperature, and a 10% reduction in cycle time.

Fundamentally, the introduction of recycled resins and alternative-sourced plastics into the supply chain will drive the need to reformulate both processes and products. Existing products will need to be updated so performance is maintained when recycled resin is incorporated, for example. And there is also a need to look back upstream, with polymer manufacturers designing resins that take into account future recycling. All this needs to be done while retaining the existing performance and – importantly – cost of virgin materials.

‘Whether working with recycled materials or looking to alternative polymer sources, analytical characterisations will be a key contributor to success,’ says Chen. ‘TA Instruments thermal and rheological instruments provide the most comprehensive analysis to polymer industries in product innovation, troubleshooting, and processing optimisation.’

No comments yet