The product life cycle of polymers - starting from their development and manufacturing to their disposal and recycling - is an increasingly critical topic for the global community and industrial partners. R&D scientists from aerospace to consumer electronics face challenges in developing the next generation of polymers with high-performance, multifunctional capabilities that also meet society’s demands for environmental sustainability. We need new materials that originate from natural and renewable material sources and that are degradable or easily recycled, and which produce less waste, and we need them fast. Fortunately, the continual march of scientific progress promises faster answers than in the past.

Computer-driven molecular design, with its ability to generate massive quantities of simulated data, facilitates entry into new frontiers of chemical discovery for environmentally sustainable materials design. It brings the promise of speed and accuracy, and it allows R&D scientists to scan through large molecular space to triage down and experimentally test only the most promising chemistries.

A paradigm shift to computer-driven molecular design is occurring throughout the polymer industry

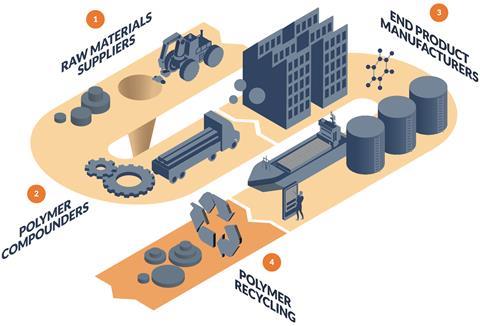

Physics-based simulations offer reliable predictions of polymers’ structures, morphologies, properties and chemical reactivity. Recent advances in machine learning (ML), deep learning and cloud-based collaborative enterprise informatics platforms have accelerated the speed, accuracy and automation of novel materials and solutions discovery. A digital chemistry strategy that leverages the combined power of atomic scale simulations, ML and collaborative enterprise informatics can accelerate chemical discovery in the polymer industry, from raw materials suppliers to end-product manufacturers. It also opens new avenues for improving polymer recycling. A paradigm shift to computer-driven molecular design is occurring throughout the industry.

Value across the polymer supply chain in the transportation industry

At every stage of the value chain, modelling and simulations can enable suppliers and manufacturers to speed up development, deliver better products and get to market faster.

Raw materials suppliers

Suppliers of petrochemical and chemical feedstocks, additives, and various monomers and resins.

Impact of digital simulation:

- Develop alternative greener raw materials that are more environmentally sustainable

- Simulate the impact of degradation on modulus for a chemistry of focus

- Design new chemistries from alternative sources and discover new applications through simulating downstream products properties

- Predict polymer crosslinker performance in composite matrix resins such epoxy-amine and cyanate esters

- Simulate the interaction between thermoplastic styrene-butadiene and crosslinkers

- Speed up decision making for catalyst selection in raw materials production

- Simulate and understand catalytic mechanisms, selectivity, and reactivity in epoxy amine, urethane, and other reactions

Polymer compounders

Suppliers who prepare polymer formulations by mixing and/or blending polymers and additives into process-ready products.

Impact of digital simulation:

- Develop greener formulations that are more environmentally sustainable

- Simulate and screen for optimal formulation with new bio-based chemistry

- Predict the performance of alternative raw materials in formulations and end products

- Predict glass transition, thermal stability and thermal expansion of new polymers

- Quantify the diffusion of additives in polymers

- Understand water transport and morphological stability of polymer formulations

- Efficiently optimise formulation properties

- Predict and track water uptake in polymer composites

- Predict curing kinetics and processing properties

End-product manufacturers

Processors of resins/formulations who make them into finished products on the market.

Impact of digital simulation:

- Design greener products that are more environmentally sustainable

- Simulate and predict properties of high-performance resins with bio-based materials and automate discovery of new biomaterials

- Enable reliable decision-making through predictive modeling of end-product properties

- Predict tire materials performance with different additives and cross-linkers

- Obtain best chemistry from upstream suppliers by targeted chemical design to properties critical to product and processing constraints

- High-throughput screening of epoxy-amine reactions to identify the unique combinations for target properties

- Accelerate the manufacturing process pipeline

- Predict polymer gelling during manufacturing process

- Quickly screen and identify potential causes and impacts of manufacturing and material source deviations

- Predict sensitivity of matrix to cleaning solvents

Polymer recycling

Research and design for recyclability throughout the polymer supply chain.

Impact of digital simulation:

- Design polymers for recyclability

- Predict selectivity of chemical recycling reaction

- Expand use of recycled materials

- Simulate impact of recycled polymers in packaging

- Determine impact on product with use of recycled material

- Screen for property changes with recycling driven microstructure changes

Driving the development of bio-based polymers

Bio-based polymers have been of great interest to scientists and industries because they originate from natural material sources and have the promise of improved degradability. Moreover, bio-based polymers can open up new chemical design space because new monomers can be designed through enzymatic processing of biomass. However, shifting to bio-based polymers raises risks in product design and development timelines. Traditionally, new materials development can take 10–20 years and product requirements are rapidly outpacing materials development. During the past decade, scientists have been looking for new approaches to speed up materials development and meet industry demands.

Our recent webinar explores the impact of molecular simulations on the development of bio-based polymers development. Watch it now to gain valuable insights on how molecular simulations enable faster and lower cost solutions for materials design and development needs, and see demonstrations through case studies and more:

- Predict structure and property for bio-based polymer mixtures

- Simulate polyethylene glycol (PEG) and polylactic acid (PLA) miscibility

- Simulate the behavior of bio-based polymers in solution

- Simulate and screen biosurfactants for optimized formulation properties

No comments yet