A recent study suggests that around 40% of drugs with market approval exhibit poor water solubility and although this is not a new problem, solutions like those offered by Johnson Matthey are still relevant to today’s pharma market

As the pharmaceutical industry turns to more complex chemical entities with increased molecular weight, enhancing solubility is becoming a key drug development challenge. Solid form and particle technologies provide drug manufacturers with powerful tools to improve the physicochemical properties of an active pharmaceutical ingredient (API), and address its aqueous solubility. Johnson Matthey (JM), a global leader in applied science and sustainable technologies, is leveraging its expertise in solid form and particle technologies to help build a healthier tomorrow.

In recent years, the drug discovery process has shifted towards increasingly insoluble APIs. Research currently estimates that 80% of drug substances in development may exhibit solubility problems.1 Poorly soluble drugs present a sizeable challenge to the industry due to their low oral bioavailability, which greatly influences the effectiveness of a drug product. A number of techniques have emerged for tackling insolubility and ensuring optimal physicochemical properties for an API. These methods are typically based on screening and manipulating the solid form of a drug candidate. Identifying an ideal solid form of an API early in drug development can not only improve the pharmacokinetic profile, but can also allow for an easier manufacturing workflow and increased stability.

The co-crystal maze

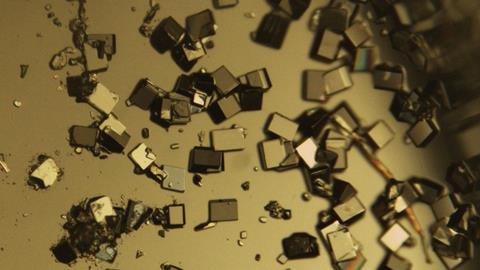

Historically, crystalline materials have been preferred in drug development owing to their greater thermodynamic stability, reproducible nature and tendency to be isolated in a higher purity than their amorphous counterparts. The traditional technique for optimising (and usually increasing) the solubility of crystalline drugs includes investigating the various salt forms of the molecule. This technique has been heavily favoured as a large majority of pharmaceutical materials possess a combination of acidic and/or basic ionisable centres, making them suitable candidates for salt formation.

Co-crystal drug designs provide new opportunities to exploit intellectual property

Co-crystals can provide an innovative route to enhance solubility, dissolution and alter other physicochemical properties of an API. Pairing an API with a suitable coformer compound in a co-crystal can assist in enhancing the desired physical properties, including both solubility and stability. Compared to salt selection, a distinct advantage of co-crystal formation is its broader potential for APIs that do not possess ionisable centres and are unable to form salts. Co-crystal screening and development is becoming an increasingly popular step in modern drug development.

Co-crystal screening is important not just for solid form optimisation but also for ensuring a full understanding of the intellectual property (IP) landscape. This is because co-crystal drug designs provide new opportunities to exploit IP. Navigating the steep learning curves of intellectual property law and regulation can often present a challenging hurdle for pharma companies. It is therefore crucial that robust and scalable processes are applied to gain detailed insights into the alternate solid forms associated with the drug product. This helps ensure that when patent applications are filed they will stand the test of time when challenges are made by rival companies. At JM, we leverage our scientific knowledge and our manufacturing capabilities to provide our customers with a variety of methods to enhance their drug discovery with differentiating process IP.

Polymorphism refers to the ability of solid materials – including neutral APIs, salts and co-crystals – to exist in two (or more) crystalline forms. It’s estimated that roughly 50% of APIs have more than one polymorphic form.2 Although polymorphs have the same chemical composition, the deviations in their crystal structure can result in different physicochemical properties. These differences can include variations in solubility, chemical stability and mechanical properties, which can influence both manufacturing as well as downstream processing (eg formulation). At an early stage of drug development, it is a regulatory requirement that drug developers review the different polymorphic forms of their API to establish stable and developable forms. As the API progresses through development, researchers are often focused on scaling the most thermodynamically stable form. Metastable forms can successfully be taken all the way to manufacture as long as we have a good understanding of the crystallisation parameters and boundaries of these forms to make them reproducible at scale.

To develop innovative APIs it is vital that all areas of solid form science are explored

Amorphous forms are non-crystalline solids that do not possess long-range order. As previously mentioned, amorphous solids have traditionally been viewed as less attractive than their crystalline counterparts, as they are generally less stable both chemically and from a solid form perspective. Recently, amorphous solids have gained increased attention due to their inherently higher solubility and other useful properties for pharma innovation, and we have seen significant advances in the understanding of amorphous materials. Today, with the development of particle engineering technologies – such as hot melt extrusion and spray drying – the stability of amorphous materials can be controlled to a greater extent and offer an exciting prospect for increasing the solubility and bioavailability of APIs. For amorphous materials, the energy barrier is lower for a molecule to change from the solid state to the solution state. This results in an enhanced solubility and fast dissolution. A thorough understanding of your API’s physical properties from the get-go will help steer a path.

Solid forms of tomorrow

To continue to develop innovative APIs it is vital that all areas of solid form science are explored in modern drug development. These technologies not only improve drug development, but can also enhance the physicochemical properties of already approved drugs. This is significant considering that approximately 40% of drugs with market approval exhibit poor water solubility.3 Revisiting these formulations with modern solid form methodologies can help to create safer and more efficient drug therapies.

At JM, we design our technologies to enhance quality of life. Our leading capabilities in screening optimal polymorphs, salt and co-crystal forms and progressing these forms at scale through phase-appropriate crystallisation development demonstrates how we apply our scientific expertise to create a healthier tomorrow.

References

1. T Loftsson and M Brewster, J. Pharm. Pharmacol., 2010 62, 1607 (DOI: 10.1111/j.2042-7158.2010.01030.x)

2. P Karpinski, Chem. Eng. Technol., 2006 29: 233 (DOI: 10.1002/ceat.200500397)

3. S Kalepu and V Nekkanti, Acta Pharm. Sin. B, 2015 5, 442 (DOI: 10.1016/j.apsb.2015.07.003)

No comments yet